目 录

中文摘要……………………………………………………………….Ⅰ

英文摘要….……………………………………………………………Ⅱ

第1 章 设计资料………………………………………………………4

1.1 工程概况………………………………………………………4

1.2 气象、水文、地质资料 ……………………………………4

1.3 结构抗震等级………………………………………………….4

1.4 变形缝设置…………………………………………………….4

1.5 设计依据及计算基本条件…………………………………….5

1.5.1设计依据…………………………………………………….5

1.5.2计算基本条件……………………………………………….5

第2 章 结构布置与计算简图………………………………………… 5

2.1 设计资料……………………………………………………….5

2.1.1设计标高…………………………………………………….5

2.1.2墙身做法……………………………………………………..5

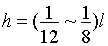

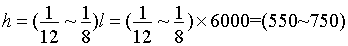

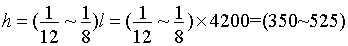

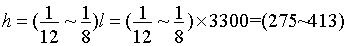

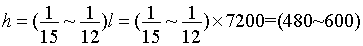

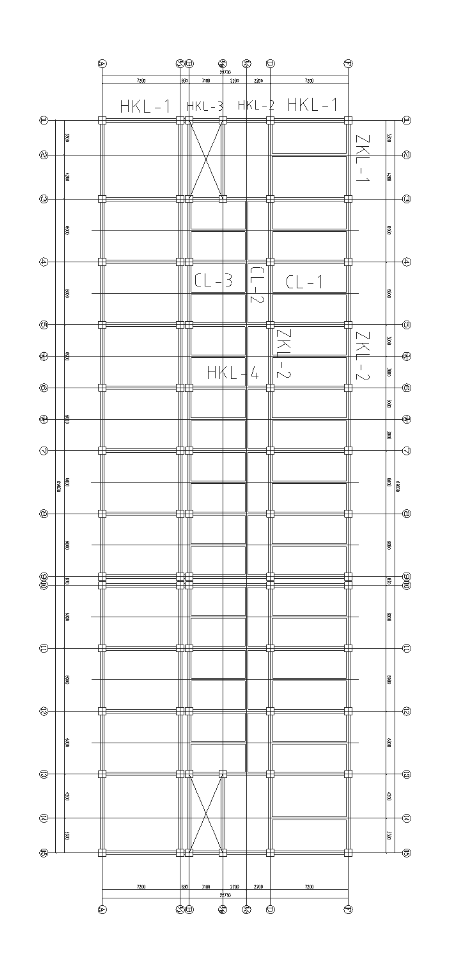

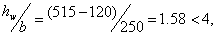

2.2梁柱截面尺寸的确定…………………………………………...5

2.2.1梁截面尺寸的确定…………………………………………..5

2.3计算简图…………………………………………………………6

2.4柱截面尺寸的确定………………………………………………8

2.5屋面板、楼面板…………………………………………………8

2.5.1楼面做法……………………………………………………...8

2.5.2屋面做法……………………………………………………...8

2.5.3门窗做法……………………………………………………...8

2.6材料的选取………………………………………………………8

第3 章 荷载计算………………………………………………………...9

3.1屋面及楼面的可变荷载标准值…………………………………9

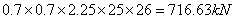

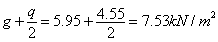

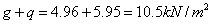

3.2重力荷载计算…………………………………………………….9

3.2.1屋面及楼面的永久荷载标准值………………………………9

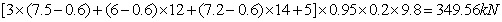

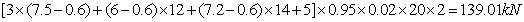

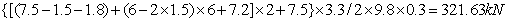

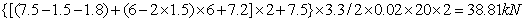

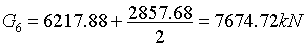

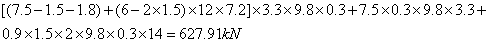

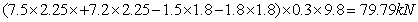

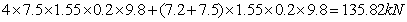

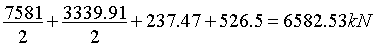

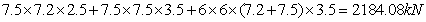

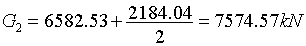

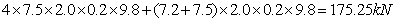

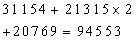

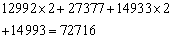

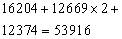

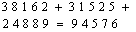

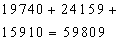

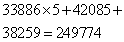

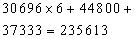

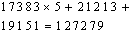

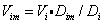

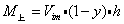

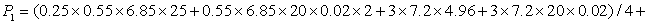

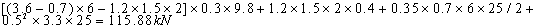

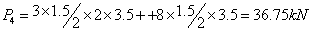

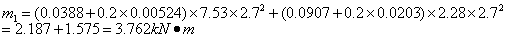

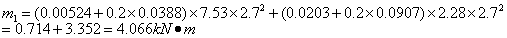

3.2.2顶层重力荷载代表值………………………………………...10

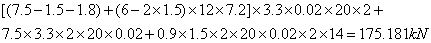

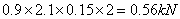

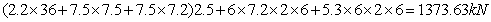

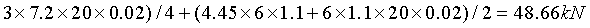

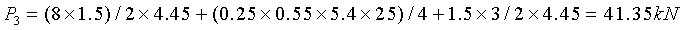

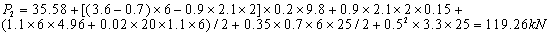

3.2.3三~五层重力荷载代表值…………………………………….11

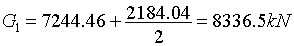

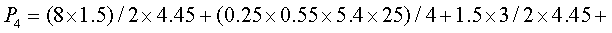

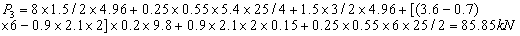

3.2.4二层重力荷载代表值………………………………………...12

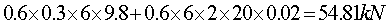

3.2.5一层重力荷载代表值………………………………………...12

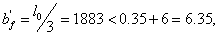

第4 章 线刚度计算……………………………………………………...14

4.1梁、柱线刚度计算………………………………………………14

4.1.1梁的线刚度计算……………………………………………...14

4.1.2柱的线刚度计算……………………………………………...14

第5 章 地震作用下内力和侧移计算…………………………………...17

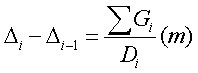

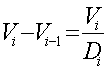

5.1横向水平荷载作用下框架结构的内力和侧移计算……………17

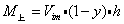

5.1.1自振周期计算………………………………………………...17

5.1.2水平地震作用及楼层地震剪力计算………………………...18

5.1.3变形验算………………………………………………….19

5.1.4地震作用下框架的内力分析…………………………….20

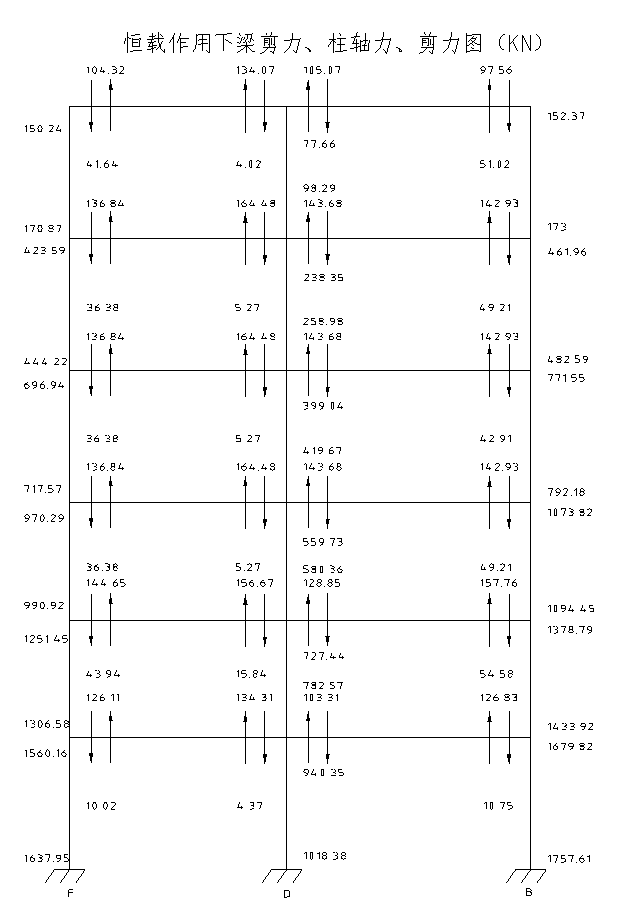

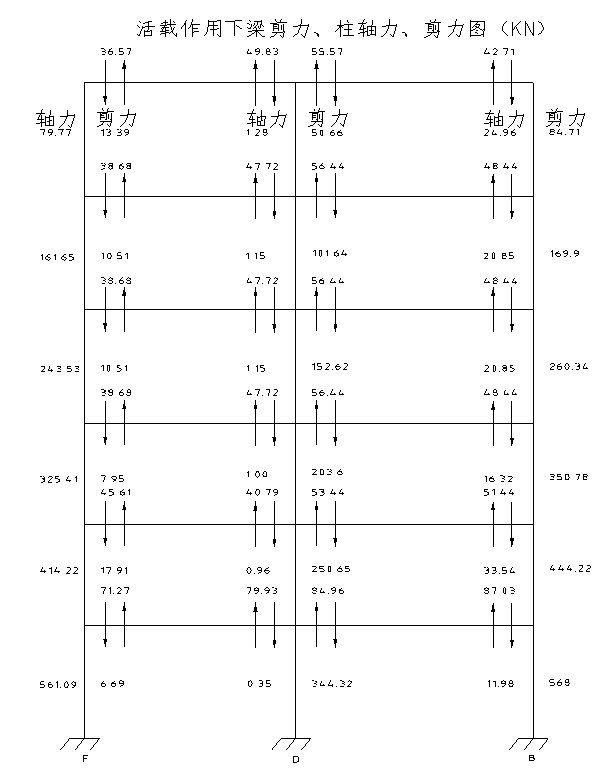

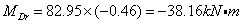

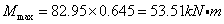

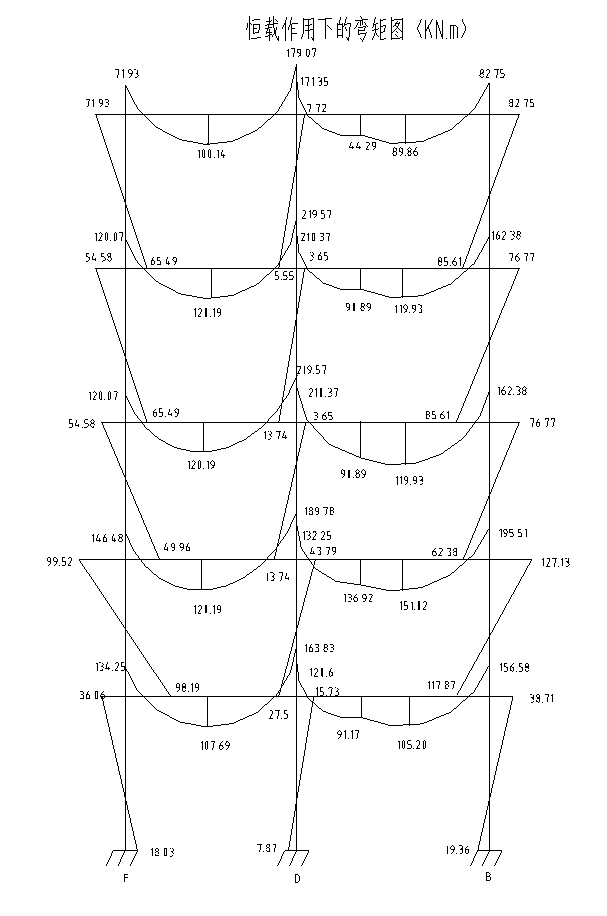

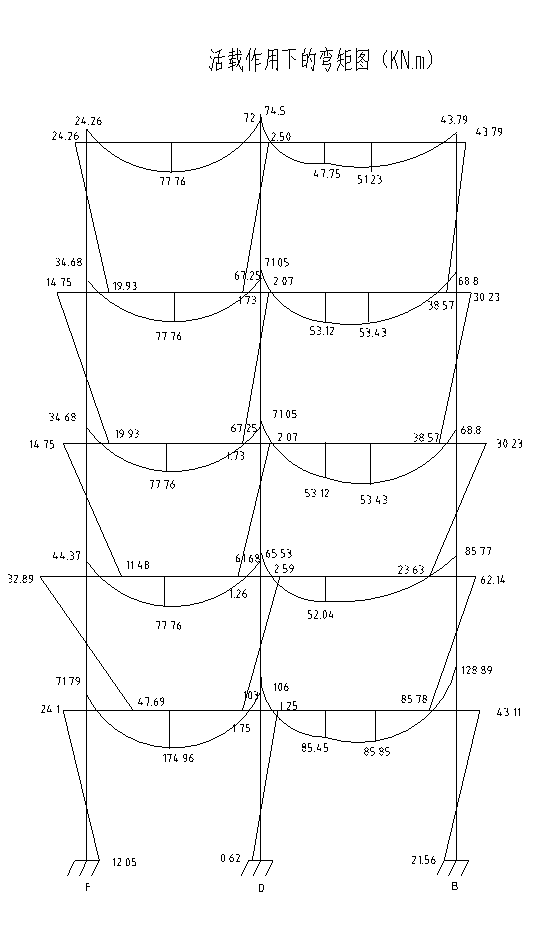

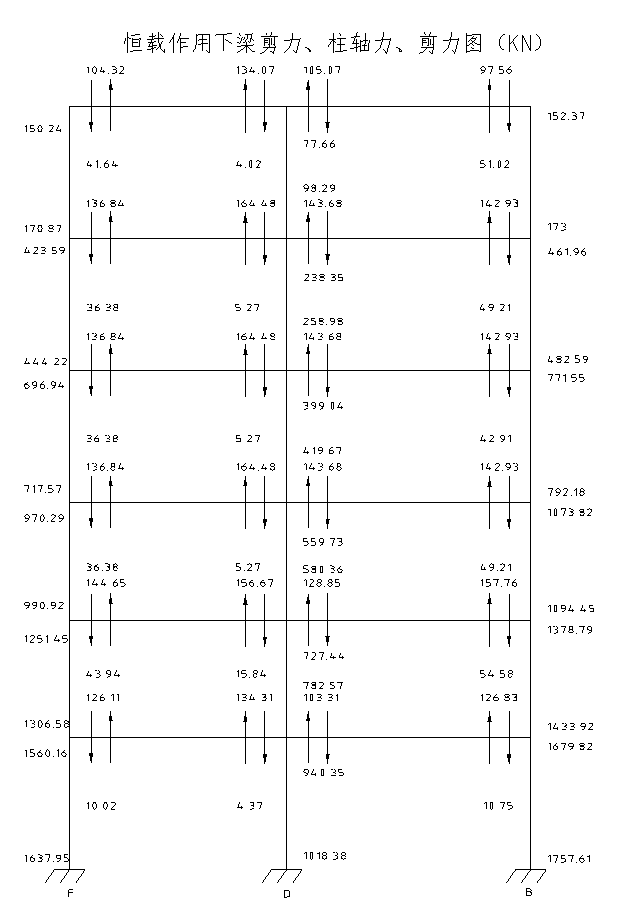

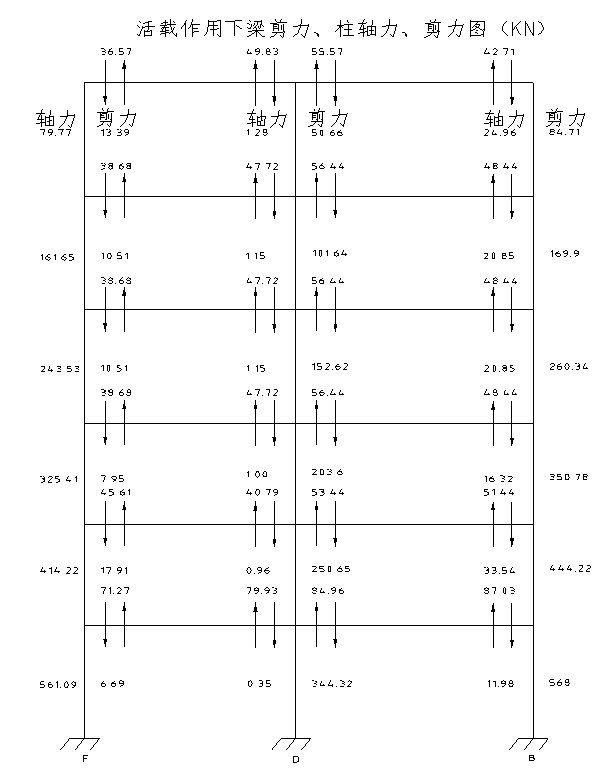

第6 章 竖向荷载作用下内力计算………………………………….22

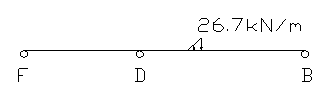

6.1竖向荷载作用下框架结构的内力计算……………………..22

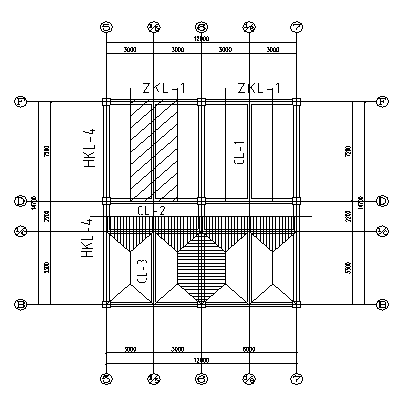

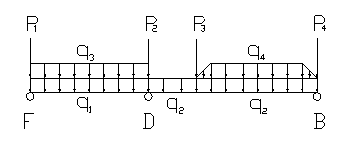

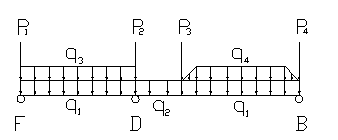

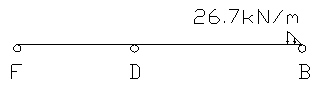

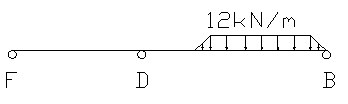

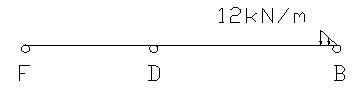

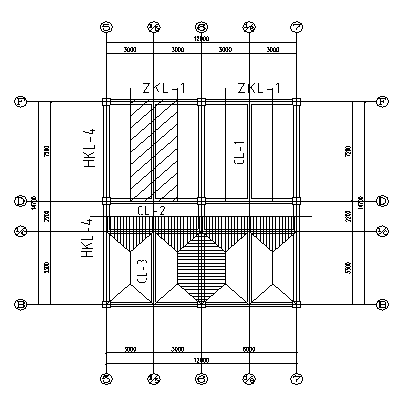

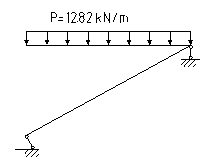

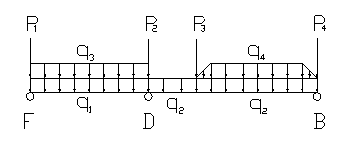

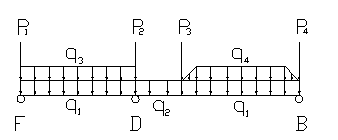

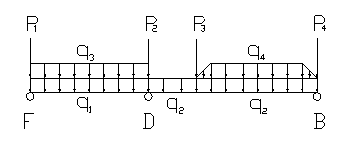

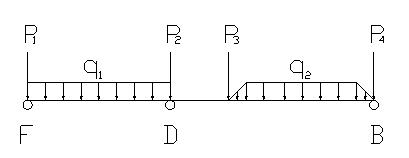

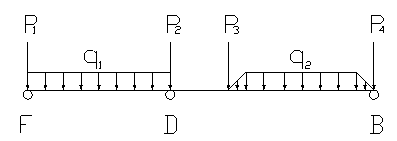

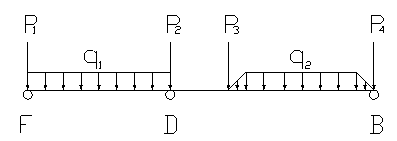

6.1.1计算单元………………………………………………….22

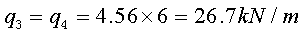

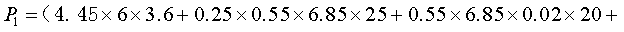

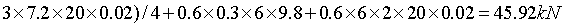

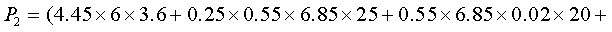

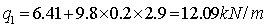

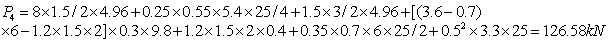

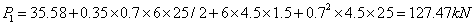

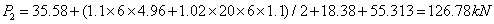

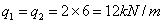

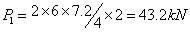

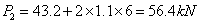

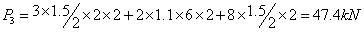

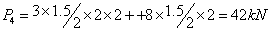

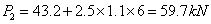

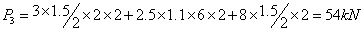

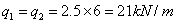

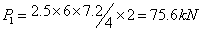

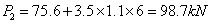

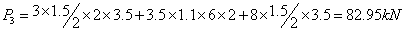

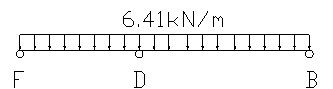

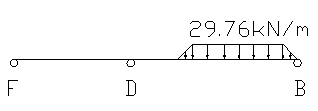

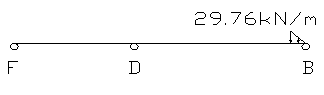

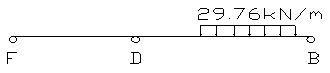

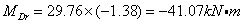

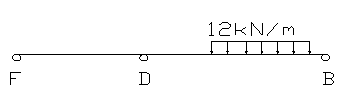

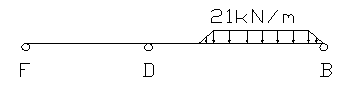

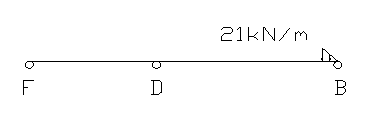

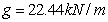

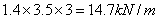

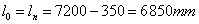

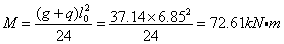

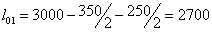

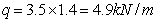

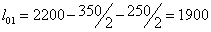

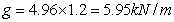

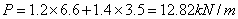

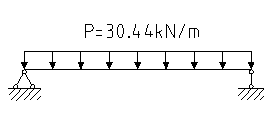

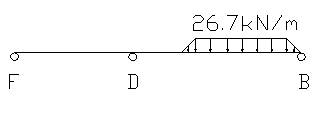

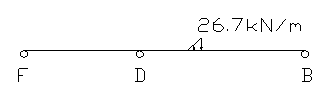

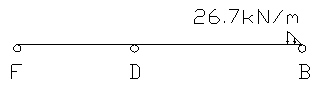

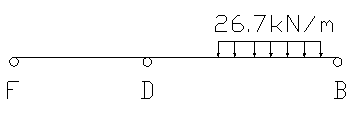

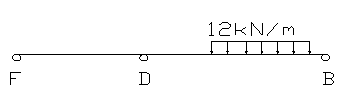

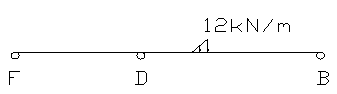

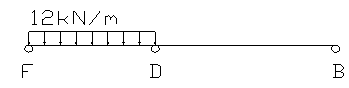

6.1.2荷载计算………………………………………………….23

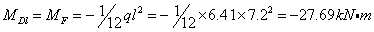

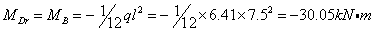

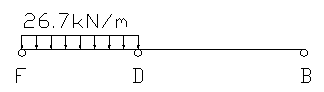

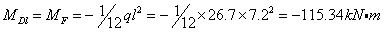

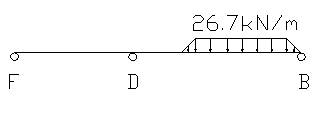

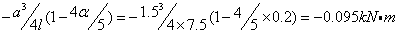

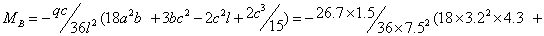

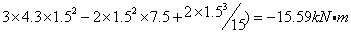

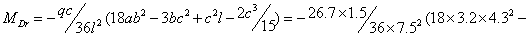

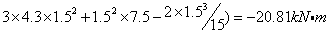

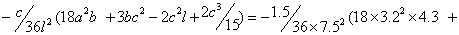

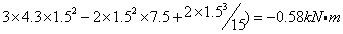

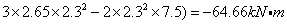

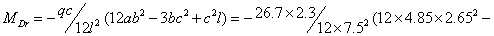

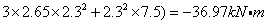

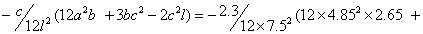

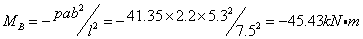

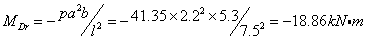

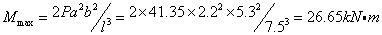

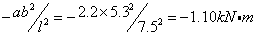

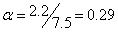

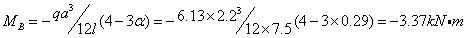

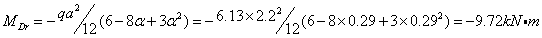

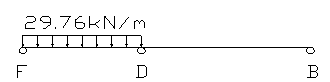

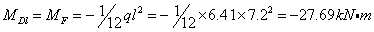

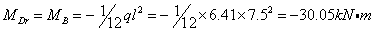

6.1.3内力计算………………………………………………….26

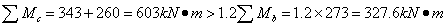

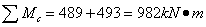

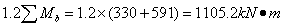

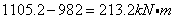

第7 章 框架内力组合……………………………………………….40

7.1横向框架内力组合…………………………………………..40

7.1.1结构抗震等级…………………………………………….40

7.1.2框架柱的内力组合……………………………………….41

7.1.3框架梁的内力组合……………………………………….45

第8 章 截面设计…………………………………………………...48

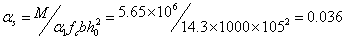

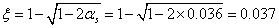

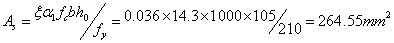

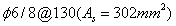

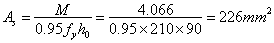

8.1框架梁………………………………………………………..48

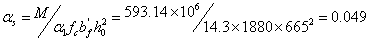

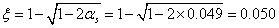

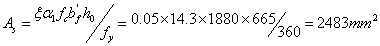

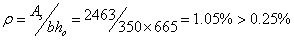

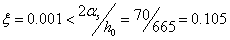

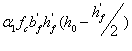

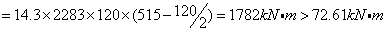

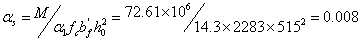

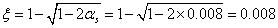

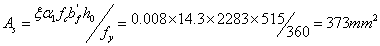

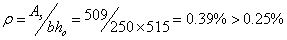

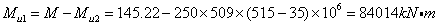

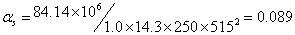

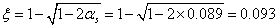

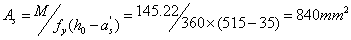

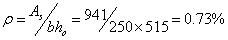

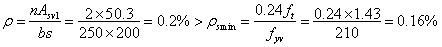

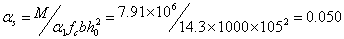

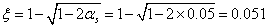

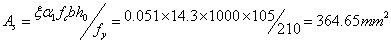

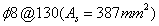

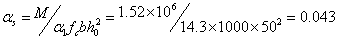

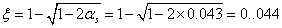

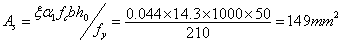

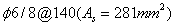

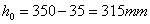

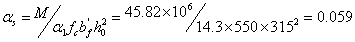

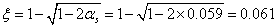

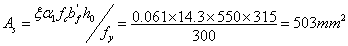

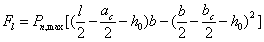

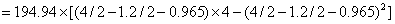

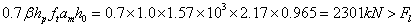

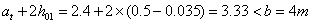

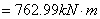

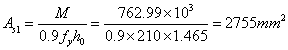

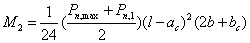

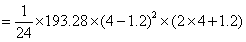

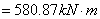

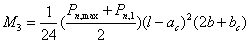

8.1.1正截面受弯承载力计算………………………………….48

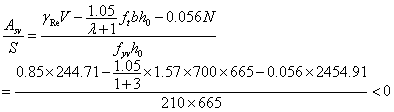

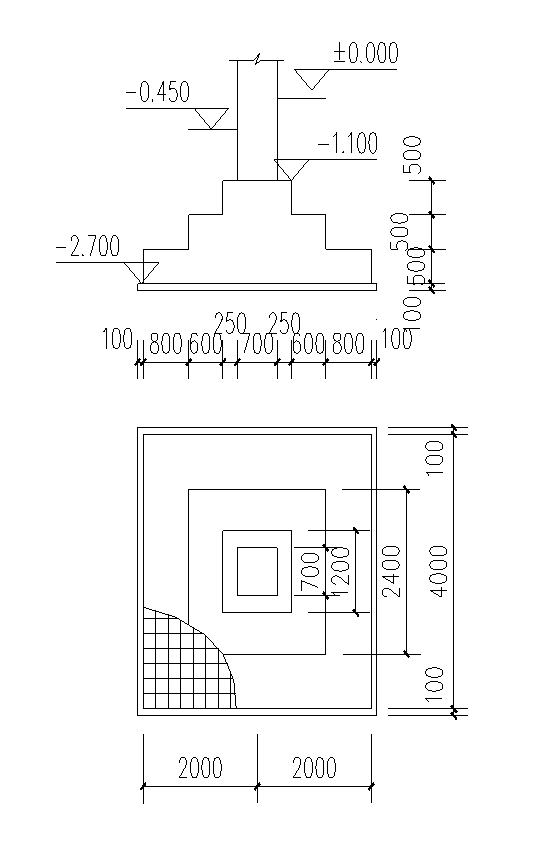

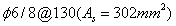

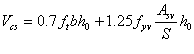

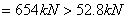

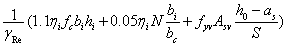

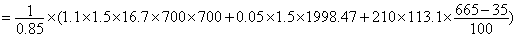

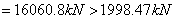

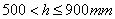

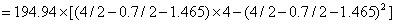

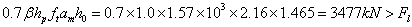

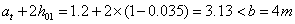

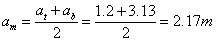

8.1.2.斜截面受剪承载力计算………………………………….50

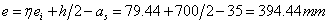

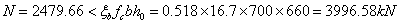

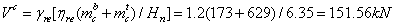

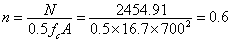

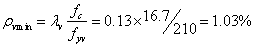

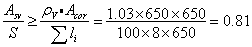

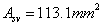

8.2框架柱………………………………………………………..50

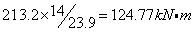

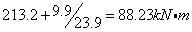

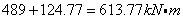

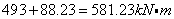

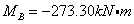

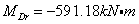

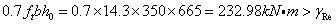

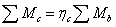

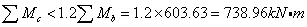

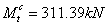

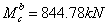

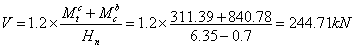

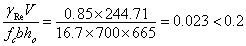

8.2.1柱端弯矩调整…………………………………………….50

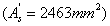

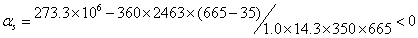

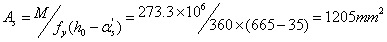

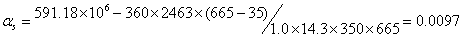

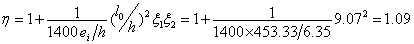

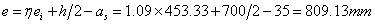

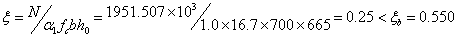

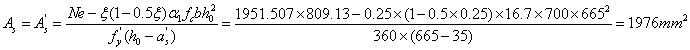

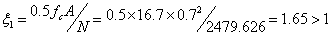

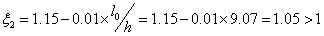

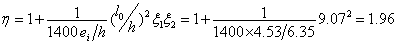

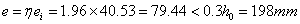

8.2.2正截面设计……………………………………………….51

8.2.3斜截面设计……………………………………………….52

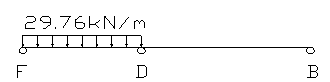

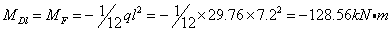

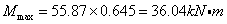

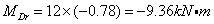

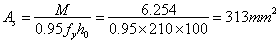

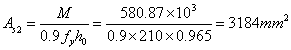

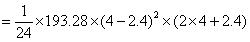

8.3次梁设计……………………………………………………..53

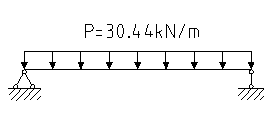

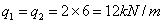

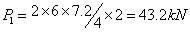

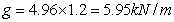

8.3.1.荷载计算………………………………………………….53

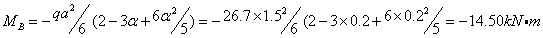

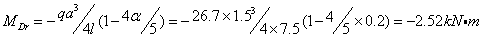

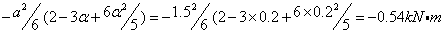

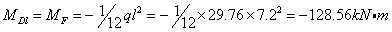

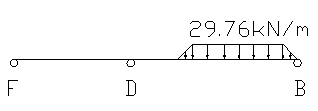

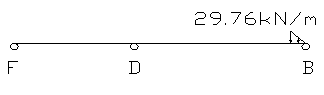

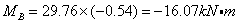

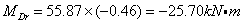

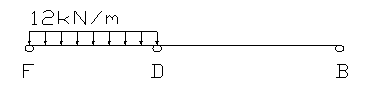

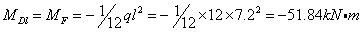

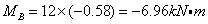

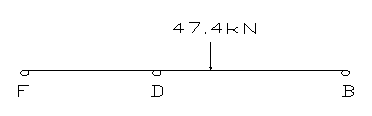

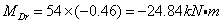

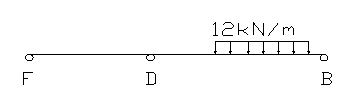

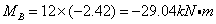

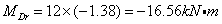

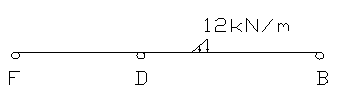

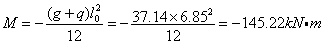

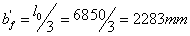

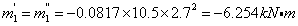

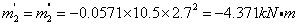

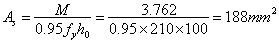

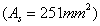

8.3.2.计算弯矩………………………………………………….53

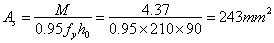

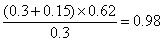

8.3.3梁正截面配筋计算……………………………………….53

8.3.4梁斜截面配筋计算……………………………………….54

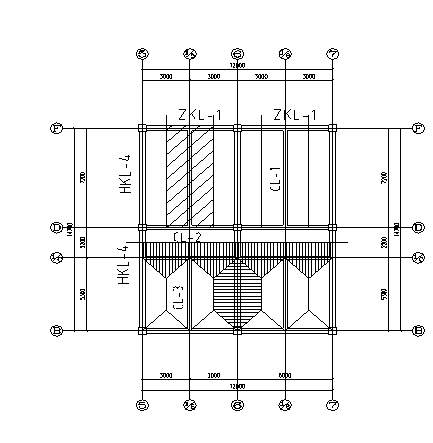

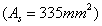

8.4 板的设计…………………………………………………….55

8.4.1单向板的设计…………………………………………….55

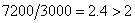

8.4.2双向板设计……………………………………………….56

8.5楼梯计算……………………………………………………..57

8.5.1梯段板设计…………………………………………….....57

8.5.2平台板设计……………………………………………….58

8.5.3平台梁设计……………………………………………….59

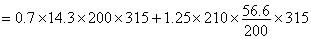

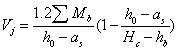

第9 章 节点设计………………………………………………….....60

9.1节点设计……………………………………………………..60

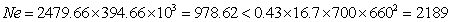

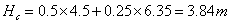

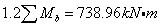

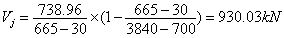

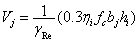

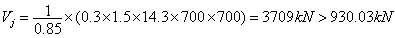

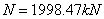

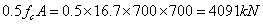

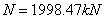

9.1.1节点核心区剪力设计值………………………………….60

9.1.2节点核心区截面验算…………………………………….61

9.1.3节点核心区截面抗剪强度计算………………………….61

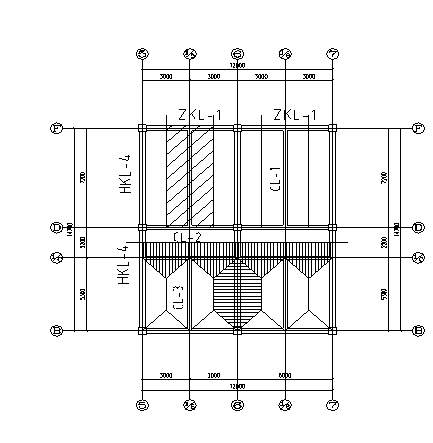

第10章 基础设计……………………………………………………61

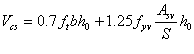

10.1 基础设计……………………………………………………61

10.1.1构造要求…………………………………………………61

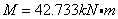

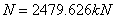

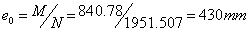

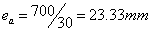

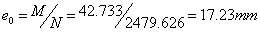

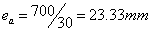

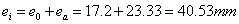

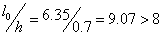

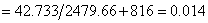

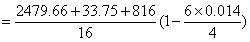

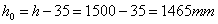

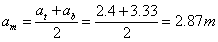

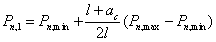

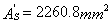

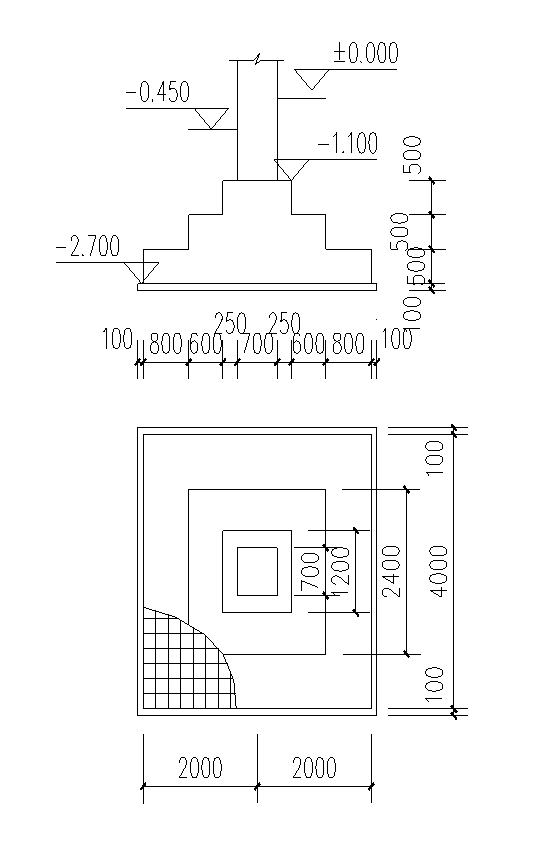

10.1.2边柱基础计算……………………………………………62

第11章 PKPM计算结果……………………………………………67

第12章 参考资料…………………………………………………….84

第13章 外文翻译…………………………………………………….85

致谢信………………………………………………………………….96

荣资商城2号楼工程设计书

第1章 设计资料

1.1工程概况:

荣资商城2号楼位于包头市钢铁大街北,为6层框架结构,总建筑面积为5042.52m , 1-2层为商场,3-6层为写字楼。

, 1-2层为商场,3-6层为写字楼。

建筑及防火等级: 建筑防火等级为二级; 建筑耐火等级为二级; 耐久年限二级。

1.2气象、水文、地质资料

冬季室外温度: -20℃

日最大降雨量: 100.8mm

月最大降雨量: 229.2mm

年最大降雨量: 678.4mm

年最大降雨日数: 91.3天

最大风速: 25m/s

基本风压: 0.5KPa

主导风向: 冬季北风,夏季冬南风

积雪深度: 210mm

基本雪压: 0.25KPa

最高地下水位: -9m

土壤冻结深度: -1.5m

土壤允许承载力: 150KPa; 场地为Ⅱ类

抗震设计烈度: 8度

1.3结构抗震等级

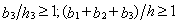

在进行建筑抗震设计时,原则上要满足三水准的抗震设防目标的要求,即“小震不坏、中震可修、大震不倒”。在具体做法上采用二阶段设计;《规范》根据房屋设防烈度、结构类型和房屋高度,将框架结构等级划分为四级,本设计为二级抗震等级。

1.4变形缝设置

变形缝包括伸缩缝、沉降缝和防震缝。

1.4.1伸缩缝要求把建筑物的墙体、楼层板、屋面等地面的上部断开,基础部分受温度影响较小,不需断开。沉降缝在有下列情况时,均需设置:

(1)同一建筑物相邻部分的高度相差较大或荷载大小相差悬殊、或结构形式变化较大,易导致地基不均匀沉降时;

(2)当建筑物各部分相邻基础的形式、宽度及埋置深度相差较大,造成基础底部压力有很大差异,易形成不均匀沉降时;

(3)当建筑物建造在不同地基上,且难于保证均匀沉降时;

(4)建筑物体型复杂、连接部位又比较薄弱时;

(5)新建建筑物与原有建筑物紧密相连时。

1.4.2防震缝在下列情况时,均需设置:

(1)建筑立面高差在6m以上;

(2)建筑物有错层且错层楼板高差较大;

(3)建筑物相邻各部分结构刚度、质量截然不同时。

防震缝的最小宽度应按《抗震规范》规定来确定:(1)当高度不超过15m时,可采用70mm;(2)当高度超过15m时,对于6度、7度、8度、9度抗震设防地区,建筑物每增高5m、4m、3m、2m时,缝宽增加20mm。本设计建筑高度为24m,则防震缝宽度为130mm。

根据以上规定,本设计设置130mm的变形缝。

1.5设计依据及计算基本条件

1.5.1设计依据

1 《建筑结构荷载规范》GB50009—2001

2 《混凝土结构设计规范》GB50010—2002

3 《建筑抗震设计规范》GB50011—2001

1.5.2计算基本条件

1 设计使用年限为50年

2建筑及防火等级: 建筑防火等级为二级; 建筑耐火等级为二级; 耐久年限二级;安全等级为二级,结构重要性系数取1.0

3 设计基本地震加速度:0.2g

4 设计地震分组:第一组

5 场地按二类场地考虑

第2章 结构布置与计算简图

2.1设计资料

2.1.1设计标高:室内标高±0.000,室内外高差450mm。

2.1.2墙身做法:墙身为混凝土空心砌块填充墙,外墙300mm,内墙200mm,用M5混合砂浆砌筑。

2.2梁柱截面尺寸的确定

2.2.1梁截面尺寸的确定:梁的截面尺寸,应符合下列要求:

1截面高度小于或等于800mm时,为50mm的倍数;截面高度大于800mm时,为100mm的倍数。

2现浇结构中主梁与次梁高度应相差50mm。

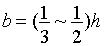

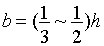

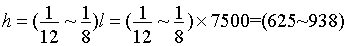

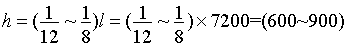

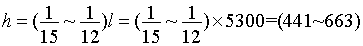

3框架梁截面高度根据跨度、约束条件和荷载大小进行选择,一般取梁高

4为了防止梁发生剪切破坏,梁高h≤1/4净跨。

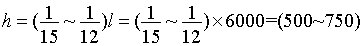

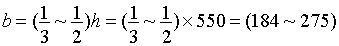

5框架梁截面宽度可取 ,梁宽b不宜小于柱宽的

,梁宽b不宜小于柱宽的 ,且不小于250mm。

,且不小于250mm。

6次梁高度宽度 ,且不小于梁高的1/4。

,且不小于梁高的1/4。

7现浇结构中,主梁截面的宽度不应小于250mm,次梁截面的宽度不应小于200mm。

根据以上规定,初步拟订梁截面尺寸:

框架梁:

7500mm跨:

7200mm跨:

6000mm跨:

4200mm跨:

3300mm跨:

次梁:

7200mm跨:

5300mm跨:

6000 mm跨:

取次梁高

取次梁宽

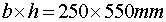

取次梁宽 ,次梁截面

,次梁截面

综上可知:

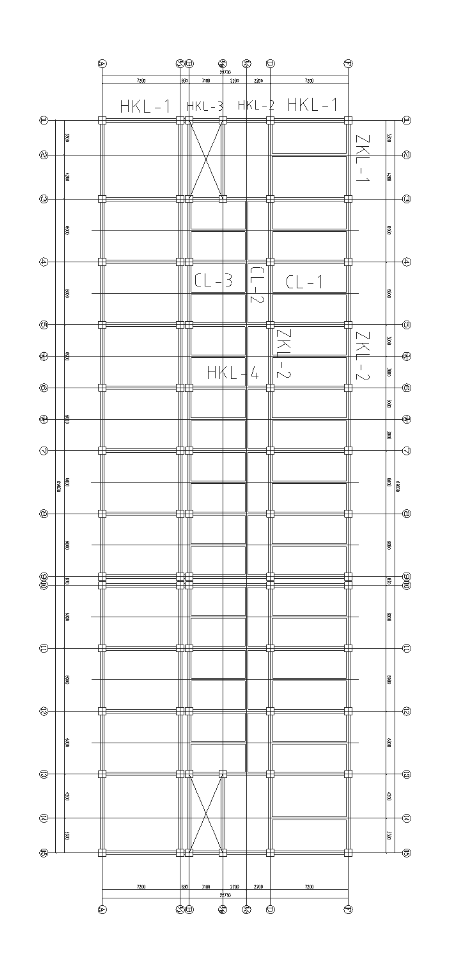

2.3计算简图:

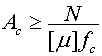

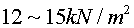

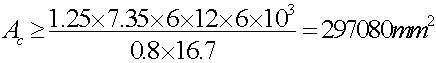

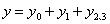

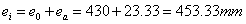

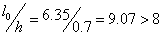

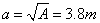

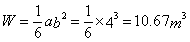

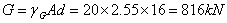

2.4柱截面尺寸的确定:柱截面尺寸有轴压比和经验来初步确定:

柱组合的轴压比设计值

柱组合的轴压比设计值

考虑地震作用组合后柱压力增大系数,边柱取1.3,不等跨内柱取1.25,等跨内柱取1.2

考虑地震作用组合后柱压力增大系数,边柱取1.3,不等跨内柱取1.25,等跨内柱取1.2

按简支状态计算的柱的负载面积

按简支状态计算的柱的负载面积

折算在单位建筑面积上的重力荷载设计值,可根据实际荷载计算,也可以近似取为

折算在单位建筑面积上的重力荷载设计值,可根据实际荷载计算,也可以近似取为

验算柱截面的上楼层层数

验算柱截面的上楼层层数

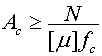

柱截面面积

柱截面面积

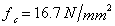

混凝土轴心抗压强度设计值

混凝土轴心抗压强度设计值

框架柱轴压比限值,对一、二、三级抗震等级,分别取0.7、0.8、0.9

框架柱轴压比限值,对一、二、三级抗震等级,分别取0.7、0.8、0.9

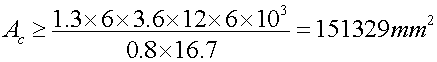

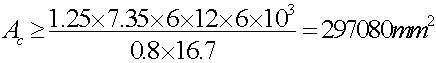

边柱:

中柱:

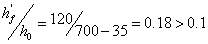

根据上述计算结果并考虑其他因素,取柱截面1~2层为700×700mm、3~6层为500×500mm

2.5屋面板、楼面板采用120mm

2.5.1楼面做法:

20厚大理石板铺实拍平、水泥浆擦缝

30厚 干硬性水泥砂浆结合层

干硬性水泥砂浆结合层

20厚 水泥砂浆找平

水泥砂浆找平

120厚现浇钢筋混凝土楼板

20厚水泥砂浆找平

2.5.2屋面做法:

防水卷材SBS

20厚 水泥砂浆找平

水泥砂浆找平

100厚水泥蛭石保温层

120厚现浇钢筋混凝土楼板

20厚水泥砂浆顶棚抹灰

2.5.3门窗做法:门采用木门;窗采用钢框玻璃窗

2.6材料的选取

对梁、柱、框架节点,根据《混凝土结构设计规范》第11.2.1条,框支梁、框支柱以及一级抗震等级的框架梁、柱、节点,混凝土强度等级不应低于C30,其他结构构件,混凝土强度等级不应低于C20。

第11.22条,结构构件中的纵向受力钢筋宜选用HRB400、HRB335级钢筋,箍金宜选用HRB335、HRB400、HPB235级钢筋。

根据上述,选取混凝土等级如下:

第3章 荷载计算

3.1屋面及楼面的可变荷载标准值:

上人屋面 2.0

屋面活荷载 2.0

屋面雪荷载 S=1.0×0.25=0.25

3.2重力荷载计算

3.2.1屋面及楼面的永久荷载标准值

1.屋面荷载:

防水卷材SBS | 0.15 |

20厚 水泥砂浆找平 水泥砂浆找平 | 20×0.02=0.4 |

100厚水泥蛭石保温层 | 5.0×0.1=0.5 |

120厚现浇钢筋混凝土楼板 | 25×0.12=3.0 |

20厚水泥砂浆顶棚抹灰 | 20×0.02=0.4 |

总计 | 4.45 |

2.大理石楼面:

20厚大理石板铺实拍平、水泥浆擦缝 | 28×0.02=0.56 |

30厚 干硬性水泥砂浆结合层 干硬性水泥砂浆结合层 | 20×0.03=0.6 |

20厚 水泥砂浆找平 水泥砂浆找平 | 20×0.02=0.4 |

120厚现浇钢筋混凝土楼板 | 25×0.12=3.0 |

20厚水泥砂浆顶棚抹灰 | 20×0.02=0.4 |

总计 | 4.96 |

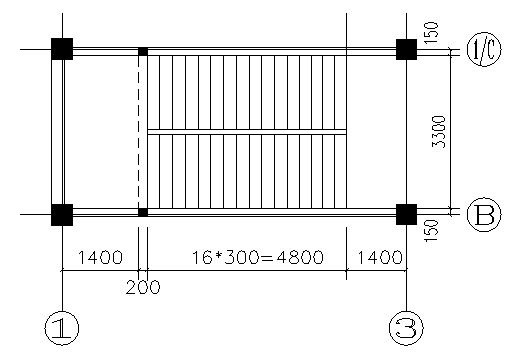

3.楼梯板:

水磨石面层 | (0.3+0.15)×0.65/0.3=0.98 |

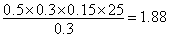

三角形踏步 | 0.5×0.3×0.15×25/0.3=1.88 |

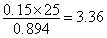

混凝土斜板 | 0.12×25/0.894=3.36 |

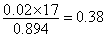

板底抹灰 | 0.02×17/0.894=0.38 |

总计 | 6.6 |

4.平台板:

水磨石面层 | 0.65 |

70mm厚混凝土板 | 0.07×25=1.75 |

板底抹灰 | 0.02×17=2.74 |

总计 | 2.74 |

3.2.2顶层重力荷载代表值:

~轴

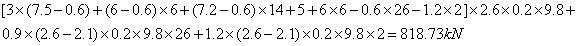

1.屋面板:(6×6+7.5+0.6)×(7.2+7.5+0.6)×4.45=3002.55

2.梁自重:

ZKL—1 0.35×0.58×(6-0.6)×18×25=493.29

ZKL—2 0.35×0.58×(7.5-0.6)×4×25=140.07

HKL—1 0.35×0.58×(7.2-0.6)×8×25=267.96

HKL—2 0.35×0.58×(4.2-0.6)×2×25=36.55

HKL—3 0.35×0.58×(3.3-0.6)×2×25=27.41

HKL—4 0.35×0.58×(7.5-0.6)×6×25=210.11

CL—1 0.25×0.43×(7.2-0.35)×7×25=128.87

CL—2 0.25×0.43×(5.3-0.35)×6×25=115.29

CL—3 0.25×0.43×(6.0-0.35)×25=

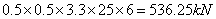

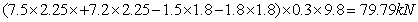

3.柱子自重:

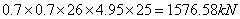

0.5×0.5×3.3/2×25×26=268.13

4.梁粉刷重

ZKL—1 [0.58×6×(6-0.6)×2+0.58×(6-0.6)-0.25×0.43×4] ×6×0.02×20=44.07

ZKL—2 [0.58×(7.5-0.6)×2+0.58×(7.5-0.6)-0.25×0.46] ×4×0.02×20=9.43

HKL—1(7.2-0.6)×0.58×2×8×0.02×20=24.50

HKL—2(4.2-0.6)×0.58×2×2×0.02×20=3.34

HKL—3(3.3-0.6)×0.58×2×2×0.02×20=3.43

HKL—4(7.5-0.6)×0.58×2×6×0.02×20=19.21

CL—1 (7.2-0.6)×0.43×2×7×0.02×20=15.89

CL—2 (5.3-0.6)×0.43×2×6×0.02×20=14.24

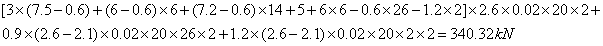

5.板粉刷:

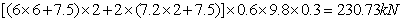

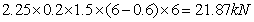

6.墙体自重:

(1)女儿墙(300厚水泥空心砖)

自重:

粉刷:

(2)顶层1/2墙体自重(内墙)

自重:

粉刷:

(3)顶层1/2墙体自重(外墙)

自重:

粉刷:

(4)玻璃幕墙:(容重 )

)

自重:

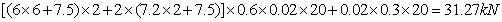

7.门窗自重:(木门容重 钢框玻璃窗容重

钢框玻璃窗容重 )

)

自重:

8.屋面活荷载:

由此,顶层重力荷载代表值为:

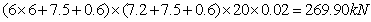

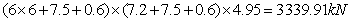

3.2.3三~五层重力荷载代表值:

~轴

梁自重、梁粉刷重、板粉刷重均与顶层相同。

1.楼面板:

2.墙体自重:

内墙

自重:  粉刷:

粉刷: 外墙

外墙

自重:

粉刷;

3.柱自重;

4.门窗自重:

由此三~五层~轴恒荷载重7681

5.楼面活荷载:

活荷载设计值:走廊、卫生间、楼梯活荷载2.5

其他:2.0

由此三~五层重力荷载代表值:

3.2.4二层重力荷载代表值:

~轴

梁自重、梁粉刷重、楼面板、板粉刷重均与三~五层相同。

二层顶部重力荷载代表值:

1.墙体自重:

玻璃幕墙:

外墙:

内墙:

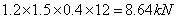

2.柱子自重:

二层恒荷载重:

3.楼面活荷载:

活荷载设计值:卫生间活荷载2.5

商场、楼梯活荷载3.5

由此二层重力荷载代表值:

3.2.5一层重力荷载代表值:

~轴

梁自重、梁粉刷重、楼面板、板粉刷重均与三~五层相同

1.二层墙体自重:

玻璃幕墙:

外墙:

内墙:

2.二层门窗自重:

3.一层墙体自重:

玻璃幕墙:

外墙:

内墙:

4.一层门窗自重:

5.柱自重:

6.活荷载与二层相同

由此一层重力荷载代表值:

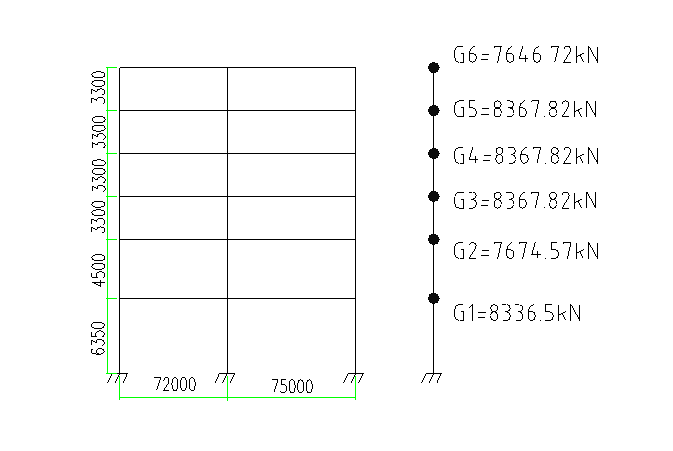

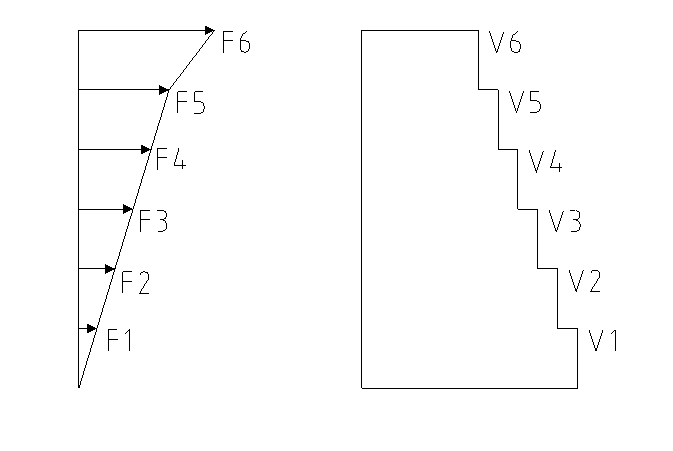

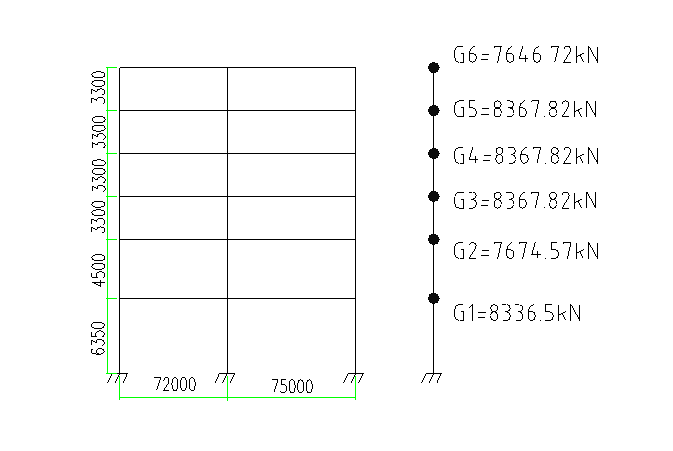

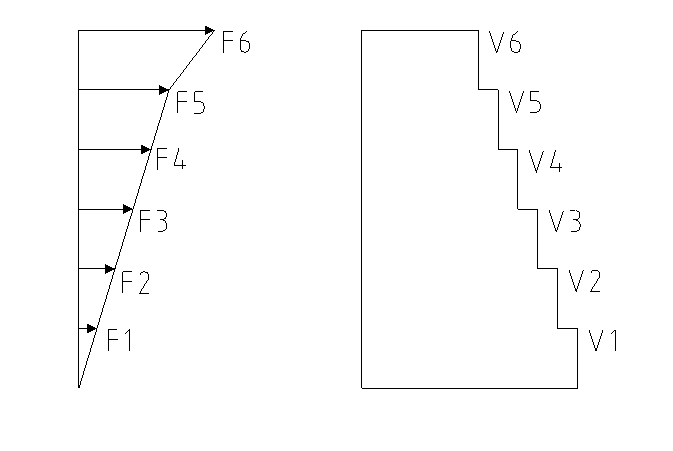

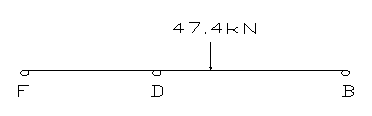

各层重力荷载代表值如图:

框架剖面图(单位m) 质点重力荷载代表值

第4章 线刚度计算

4.1梁、柱线刚度计算:

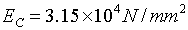

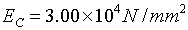

柱为混凝土C35

梁为混凝土C30

4.1.1梁的线刚度计算

4.1.2柱的线刚度计算

柱的线刚度表

轴边框架边柱

3~6 |

|

| 3.3 |

|

| 2.74 | 0.57 | 31154 |

2 |

|

| 4.5 |

|

| 0.97 | 0.33 | 27377 |

1 |

|

| 6.35 |

|

| 1.37 | 0.55 | 16204 |

轴边框架边柱

3~6 |

|

| 3.3 |

|

| 1.27 | 0.39 | 21315 |

2 |

|

| 4.5 |

|

| 0.45 | 0.18 | 14933 |

1 |

|

| 6.35 |

|

| 0.63 | 0.43 | 12669 |

轴边框架边柱

3~6 |

|

| 3.3 |

|

| 1.20 | 0.38 | 20769 |

2 |

|

| 4.5 |

|

| 0.43 | 0.18 | 14933 |

1 |

|

| 6.35 |

|

| 0.61 | 0.42 | 12374 |

轴边框架中柱

3~6 |

|

| 3.3 |

|

| 4.90 | 0.71 | 38806 |

2 |

|

| 4.5 |

|

| 1.73 | 0.46 | 38162 |

1 |

|

| 6.35 |

|

| 2.45 | 0.67 | 19740 |

轴边框架中柱

3~6 |

|

| 3.3 |

|

| 3.43 | 0.63 | 34433 |

2 |

|

| 4.5 |

|

| 1.21 | 0.38 | 31525 |

1 |

|

| 6.35 |

|

| 1.71 | 0.82 | 24159 |

轴中框架中柱

3~6 |

|

| 3.3 |

|

| 3.3 | 0.62 | 33886 |

2 |

|

| 4.5 |

|

| 1.17 | 0.37 | 30696 |

1 |

|

| 6.35 |

|

| 1.65 | 0.59 | 17383 |

轴中框架中柱

3~6 |

|

| 3.3 |

|

| 6.54 | 0.77 | 42085 |

2 |

|

| 4.5 |

|

| 2.32 | 0.54 | 44800 |

1 |

|

| 6.35 |

|

| 3.28 | 0.72 | 21213 |

轴中框架中柱

3~6 |

|

| 3.3 |

|

| 4.57 | 0.70 | 38259 |

2 |

|

| 4.5 |

|

| 1.61 | 0.45 | 37333 |

1 |

|

| 6.35 |

|

| 2.28 | 0.65 | 19151 |

轴中框架边柱

3~6 |

|

| 3.3 |

|

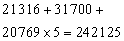

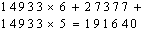

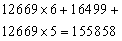

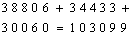

| 1.27 | 0.39 | 21316 |

2 |

|

| 4.5 |

|

| 0.45 | 0.18 | 14933 |

1 |

|

| 6.35 |

|

| 0.63 | 0.43 | 12669 |

轴中框架边柱

3~6 |

|

| 3.3 |

|

| 2.74 | 0.58 | 31700 |

2 |

|

| 4.5 |

|

| 0.97 | 0.33 | 27377 |

1 |

|

| 6.35 |

|

| 1.38 | 0.56 | 16499 |

轴中框架边柱

3~6 |

|

| 3.3 |

|

| 1.20 | 0.38 | 20769 |

2 |

|

| 4.5 |

|

| 0.43 | 0.18 | 14933 |

1 |

|

| 6.35 |

|

| 0.61 | 0.43 | 12669 |

轴边框架中柱

3~6 |

|

| 3.3 |

|

| 2.47 | 0.55 | 30060 |

2 |

|

| 4.5 |

|

| 0.87 | 0.30 | 24889 |

1 |

|

| 6.35 |

|

| 1.23 | 0.54 | 15910 |

各层D值汇总

层数 层数

D值 柱类型 | 3~6 | 2 | 1 |

角柱 |

|

|

|

边柱 |

|

|

|

中柱 |

|

|

|

中柱 |

|

|

|

|

|

|

|

第5章 地震作用下内力和侧移计算

5.1横向水平荷载作用下框架结构的内力和侧移计算:

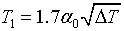

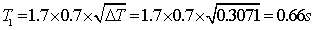

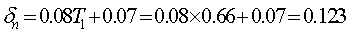

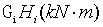

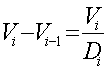

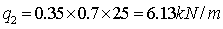

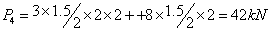

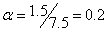

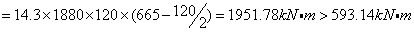

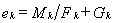

5.1.1自振周期计算

按顶点位移法计算,考虑填充墙对框架刚度的影响,取基本周期调整系数

,计算公式为

,计算公式为 ,式中

,式中 为顶点位移,按D值法计算:

为顶点位移,按D值法计算:

横向框架顶点位移法计算

层数 |

|

|

|

|

|

6 | 7646.12 | 7646.12 | 689751 | 0.0111 | 0.3071 |

5 | 8367.82 | 16014.54 | 689751 | 0.0232 | 0.296 |

4 | 8367.82 | 24382.36 | 689751 | 0.0353 | 0.2728 |

3 | 8367.82 | 32750.18 | 689751 | 0.0474 | 0.2375 |

2 | 7484.44 | 40234.62 | 594005 | 0.0677 | 0.1901 |

1 | 8336.5 | 48571.12 | 396862 | 0.1224 | 0.1224 |

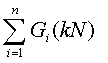

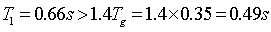

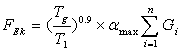

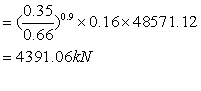

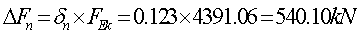

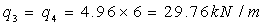

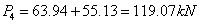

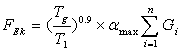

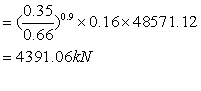

5.1.2水平地震作用及楼层地震剪力计算:

由于

,

,

故应考虑顶点附加地震作用

结构底部剪力为:

顶部附加地震作用为:

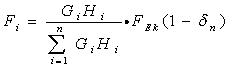

各层地震作用及楼层地震剪力

层次 |

|

|

|

|

|

|

|

6 | 3.3 | 24.05 | 7646.72 | 183903.62 | 0.243 |

|

|

5 | 3.3 | 20.75 | 8367.82 | 173632.27 | 0.229 | 881.87 |

|

4 | 3.3 | 17.45 | 8367.82 | 146018.46 | 0.193 | 743.24 |

|

3 | 3.3 | 14.15 | 8367.82 | 118404.65 | 0.156 | 600.75 |

|

2 | 4.5 | 10.85 | 7674.57 | 83269.08 | 0.110 | 423.61 |

|

1 | 6.35 | 6.35 | 8336.5 | 52936.78 | 0.069 | 265.7 |

|

水平地震作用分布 层间剪力分布

水平地震作用分布 层间剪力分布

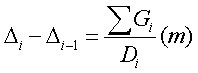

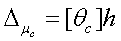

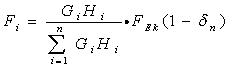

5.1.3变形验算:

层次 | 层间剪力

| 层间刚度

|

| 层高 | 层间相对 弹性转角 | 备注 |

6 | 1475.88 | 689751 | 0.0021 | 3.3 | 1/1571 | 层间转角均满足

=1/550的要求 |

5 | 2357.75 | 689751 | 0.0034 | 3.3 | 1/971 |

4 | 3100.99 | 689751 | 0.0045 | 3.3 | 1/733 |

3 | 3701.74 | 689751 | 0.0054 | 3.3 | 1/611 |

2 | 4125.35 | 594005 | 0.0069 | 4.5 | 1/652 |

1 | 4391.06 | 396862 | 0.0111 | 6.35 | 1/572 |

由表可见,最大层间位移角发生在第一层,其值为1/572 1/550。满足式

1/550。满足式

要求。

要求。

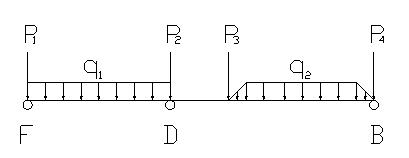

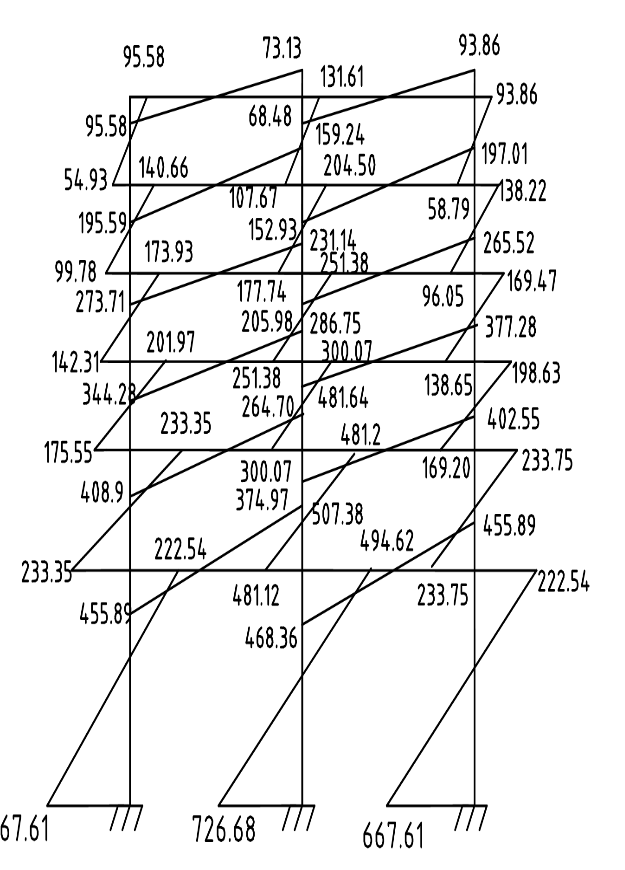

5.1.4地震作用下框架的内力分析:

层次 | 层高 | 层间 剪力 | 层间 刚度 | 轴边柱 |

|

|

|

|

|

|

6 | 3.3 | 1475.88 | 689751 | 20769 | 44.44 | 1.2 | 0.36 | 93.86 | 52.79 |

5 | 3.3 | 2357.75 | 689751 | 20769 | 70.99 | 1.2 | 0.41 | 138.22 | 96.05 |

4 | 3.3 | 3100.99 | 689751 | 20769 | 93.37 | 1.2 | 0.45 | 169.47 | 138.65 |

3 | 3.3 | 3701.74 | 689751 | 20769 | 111.46 | 1.2 | 0.46 | 198.63 | 169.20 |

2 | 4.5 | 4125.35 | 594005 | 14933 | 103.71 | 0.43 | 0.5 | 233.35 | 233.35 |

1 | 6.35 | 4391.06 | 396862 | 12669 | 140.18 | 0.61 | 0.75 | 222.54 | 667.61 |

注:    |

层次 | 层高 | 层间 剪力 | 层间 刚度 | 轴边柱 |

|

|

|

|

|

|

6 | 3.3 | 1475.88 | 689751 | 33886 | 72.51 | 3.3 | 0.45 | 131.61 | 107.67 |

5 | 3.3 | 2357.75 | 689751 | 33886 | 115.83 | 3.3 | 0.465 | 204.50 | 177.74 |

4 | 3.3 | 3100.99 | 689751 | 33886 | 152.35 | 3.3 | 0.5 | 251.38 | 251.38 |

3 | 3.3 | 3701.74 | 689751 | 33886 | 181.86 | 3.3 | 0.5 | 300.07 | 300.07 |

2 | 4.5 | 4125.35 | 594005 | 30696 | 213.83 | 1.17 | 0.5 | 481.12 | 481.12 |

1 | 6.35 | 4391.06 | 396862 | 17383 | 192.33 | 1.65 | 0.595 | 494.62 | 726.68 |

注:    |

层次 | 层高 | 层间 剪力 | 层间 刚度 | 轴边柱 |

|

|

|

|

|

|

6 | 3.3 | 1475.88 | 689751 | 21316 | 45.61 | 1.27 | 0.365 | 95.58 | 54.93 |

5 | 3.3 | 2357.75 | 689751 | 21316 | 72.86 | 1.27 | 0.415 | 140.66 | 99.78 |

4 | 3.3 | 3100.99 | 689751 | 21316 | 95.83 | 1.27 | 0.45 | 173.93 | 142.31 |

3 | 3.3 | 3701.74 | 689751 | 21316 | 114.40 | 1.27 | 0.465 | 201.97 | 175.55 |

2 | 4.5 | 4125.35 | 594005 | 14933 | 103.71 | 0.45 | 0.5 | 233.35 | 233.35 |

1 | 6.35 | 4391.06 | 396862 | 12669 | 140.18 | 0.63 | 0.75 | 222.54 | 667.61 |

注:    |

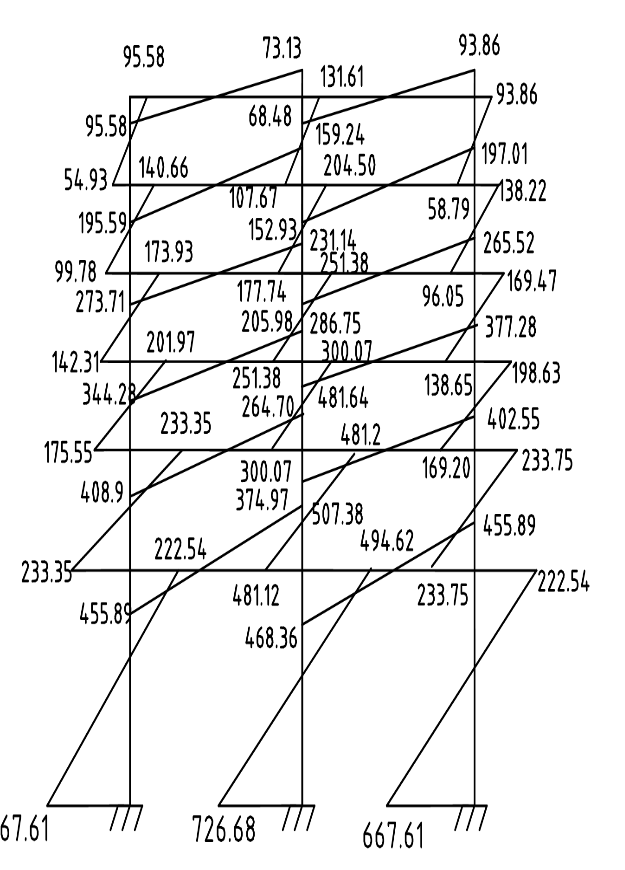

地震作用下框架梁柱弯矩图(单位: )

)

地震作用下框架梁端剪力及柱轴力图(单位: )

)

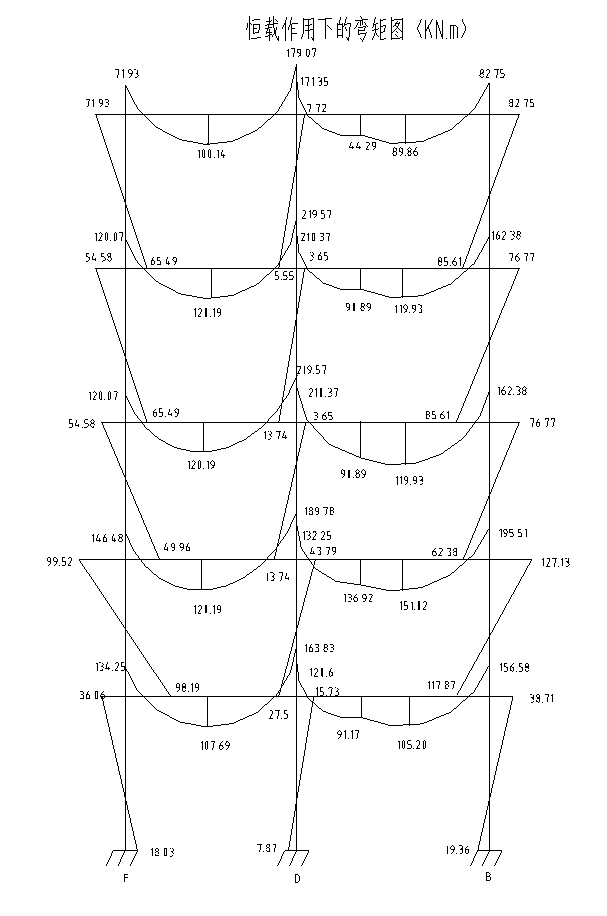

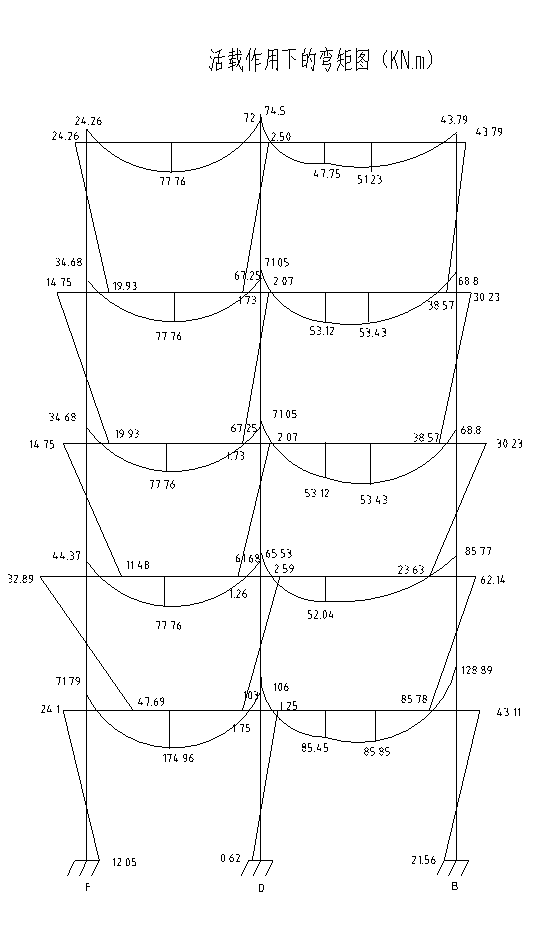

第6章 竖向荷载作用下内力计算

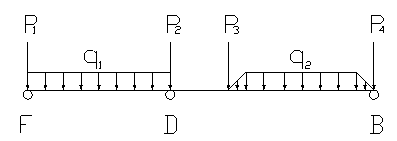

6.1竖向荷载作用下框架结构的内力计算

在竖向荷载作用下,梁端可以考虑塑性内力重分布,取弯矩调幅系数0.8,楼面竖向荷载分别按恒荷载及全部活荷载计算:

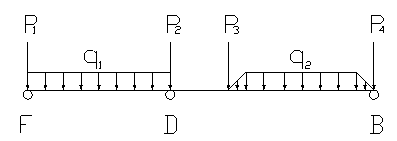

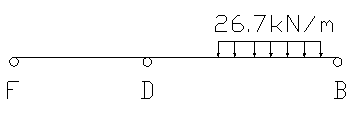

6.1.1计算单元:

D—F轴  单向板

单向板  单向板

单向板

C—D轴  双向板

双向板

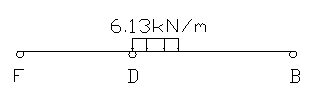

6.1.2荷载计算:

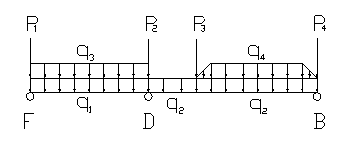

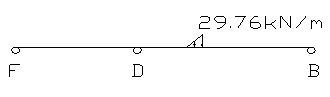

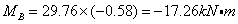

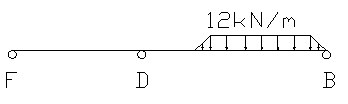

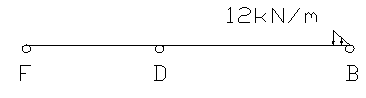

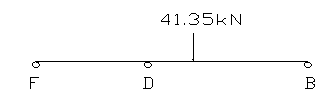

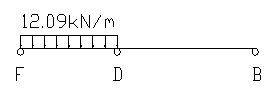

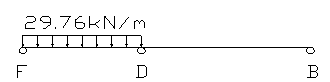

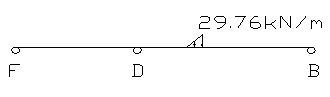

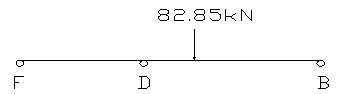

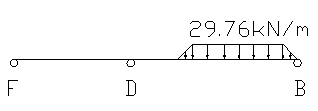

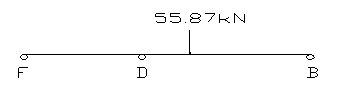

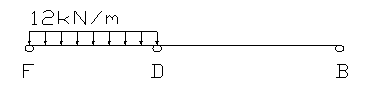

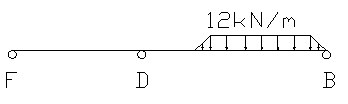

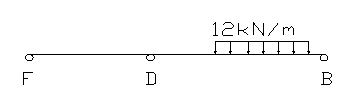

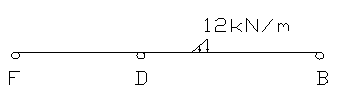

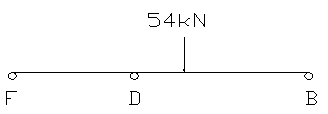

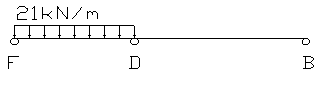

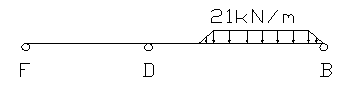

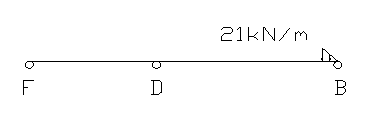

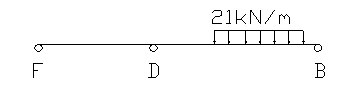

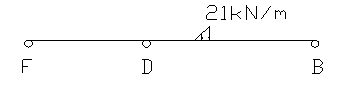

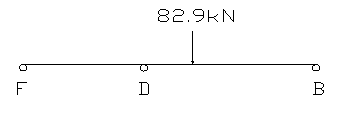

1. 恒荷载作用下各层框架梁上荷载分布如图:

(1)对于6层

图中, 为均布荷载,代表梁自重。

为均布荷载,代表梁自重。

分别为房间传给梁的均布荷载和梯形荷载。

分别为房间传给梁的均布荷载和梯形荷载。

分别为边纵梁、中纵梁传给柱的恒荷载,包括梁自重、楼面板重和女儿墙等的重力荷载:

分别为边纵梁、中纵梁传给柱的恒荷载,包括梁自重、楼面板重和女儿墙等的重力荷载:

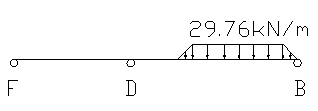

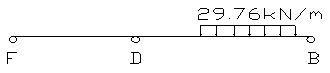

(2)对于2~5层

图中:

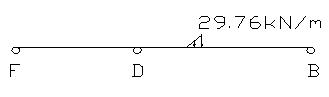

(3)对于1层

图中:

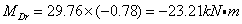

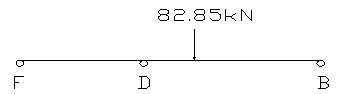

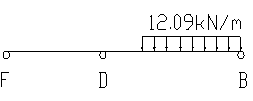

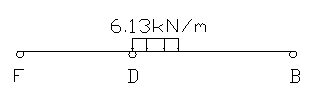

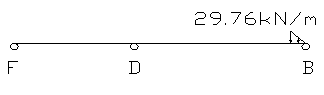

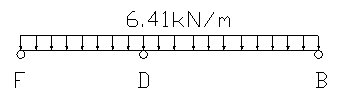

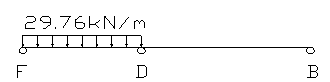

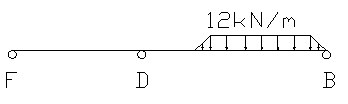

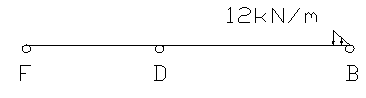

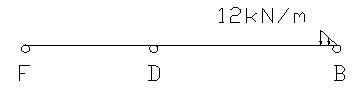

2. 活荷载作用下各层框架梁上荷载分布如图:

(1)对于6层

图中:

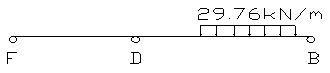

(2)对于2~5层

图中:

(3)对于1层

图中:

6.1.3内力计算

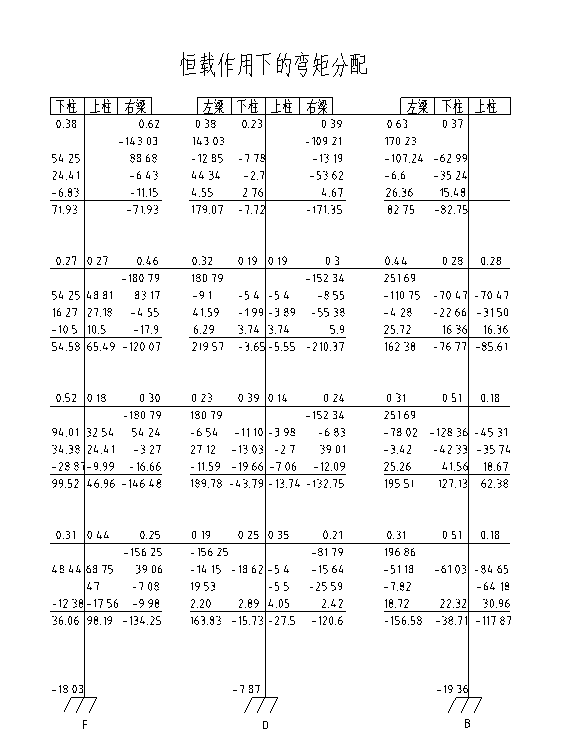

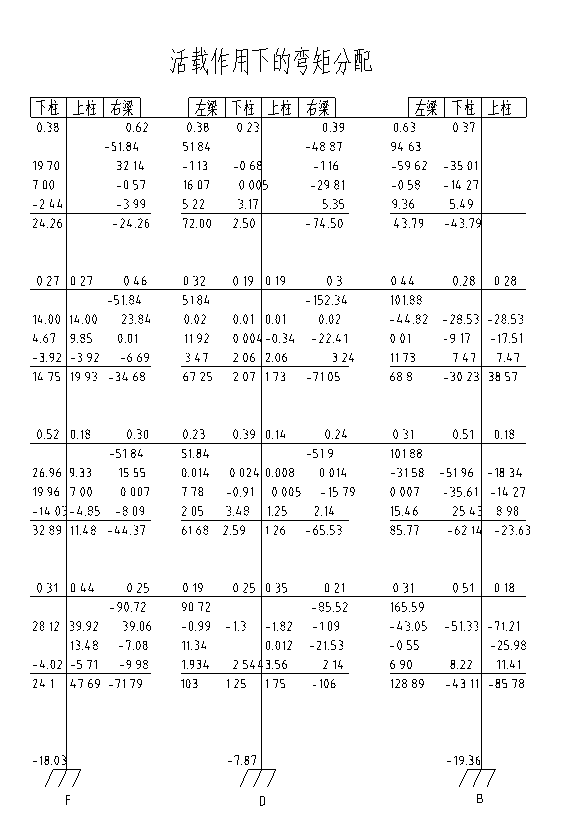

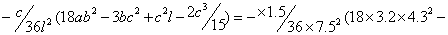

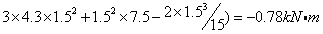

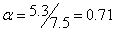

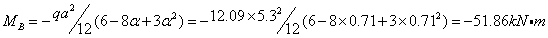

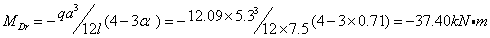

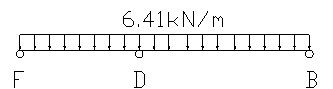

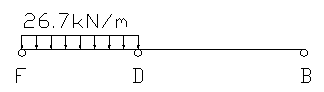

因为荷载作用比较复杂,所以需对荷载进行分解再进行叠加的方法进行。

1.恒荷载内力计算:

(1)对于6层

a

其中:

b

其中:

c

其中:

其中:

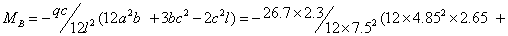

(2)对于2~5层

a

b

c

(3)对于一层

a

b

c

2.活荷载内力计算:

(1)对于6层

a

b

c

(2)对于2~5层

a

b

c

(3)对于1层

a

b

c

恒荷载作用下支座弯矩汇总

层数 | B |

|

| F |

6 | -170.23 | -109.21 | -143.03 | -143.03 |

2~5 | -251.69 | -152.34 | -180.79 | -180.79 |

1 | -196.86 | -81.79 | -156.25 | -156.25 |

活荷载作用下支座弯矩汇总

层数 | B |

|

| F |

6 | -96.43 | -48.87 | -51.84 | -51.84 |

2~5 | -101.88 | -51.9 | -51.84 | -51.84 |

1 | -165.59 | -85.52 | -90.72 | -90.72 |

第7章 框架内力组合

7.1横向框架内力组合

7.1.1结构抗震等级:

结构的抗震等级可根据结构类型、地震烈度、房屋高度等因素,本工程的抗震等级为二级。

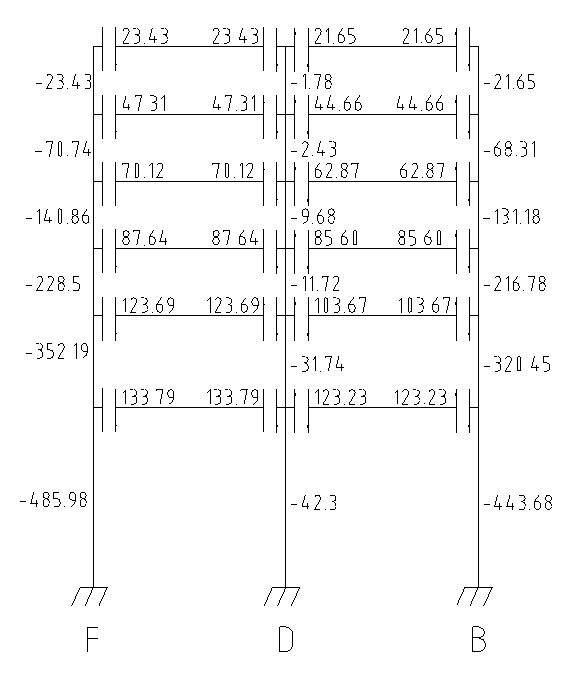

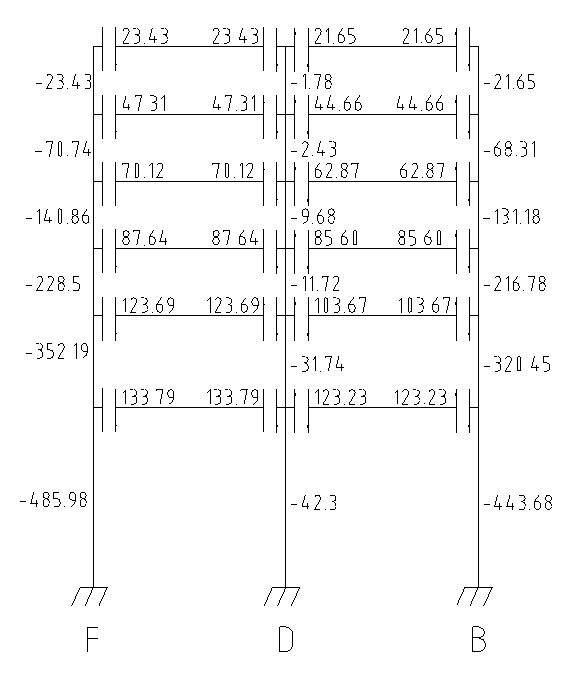

7.1.2框架柱的内力组合

7.1.3框架梁的内力组合

第8章 截面设计

8.1框架梁

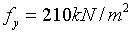

以第一层梁BD跨为例,从内力组合表中分别选出最不内力组合,并将支座中心处的弯矩换算为支座边缘控制截面的弯矩进行配筋计算,当梁下部受拉时,按T行截面设计,当梁上部受拉时按矩形截面设计,混凝土等级 ,纵向受力钢筋为三级钢筋(

,纵向受力钢筋为三级钢筋( ),箍金为一级钢筋(

),箍金为一级钢筋( )

)

根据《抗震规范》给出的钢筋混凝土结构的 的值,见下表

的值,见下表

结构构件类型 | 正截面承载力计算 | 斜截面承 载力计算 | 局部受压承载力计算 |

梁 | 偏心受压柱 | 偏心受拉柱 | 剪力墙 | 各类柱件及框架节点 | 结构的局部受压部位 |

| 0.75 | 0.8 | 0.85 | 0.85 | 0.85 | 1.0 |

注: —承载力抗震调整系数 —承载力抗震调整系数 |

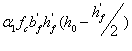

8.1.1正截面受弯承载力计算:

(1)通过内力组合得出的设计内力还需进行调整以保证梁端的破坏先于柱端的破坏(强柱弱梁的原则)、弯曲破坏先于剪切破坏(强剪弱弯的原则)、构件的破坏先于节点的破坏(强节点弱构件的原则)。

根据“强柱弱梁”的原则进行调整的思路是:对同一节点,使其在抗震作用组合下,柱端的弯矩设计值略大于梁端的弯矩设计值或抗震设计值。

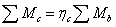

一、二、三级框架的梁柱节点处,除框支层最上层的柱上端、框架顶层和柱轴压比小于0.15者除外,柱端弯矩设计值应符合下式要求:

其中, 为节点上、下柱端截面顺时针或反时针方向组合的弯矩设计值之和,上、下柱端的弯矩设计值,一般情况可按弹性分析分配;

为节点上、下柱端截面顺时针或反时针方向组合的弯矩设计值之和,上、下柱端的弯矩设计值,一般情况可按弹性分析分配; 为节点左右梁端截面顺时针或反时针方向组合的弯矩设计值之和,节点左右梁端均为负弯矩时,绝对值较小的弯矩值应取零;

为节点左右梁端截面顺时针或反时针方向组合的弯矩设计值之和,节点左右梁端均为负弯矩时,绝对值较小的弯矩值应取零; 为强柱系数,一级为1.4、二级为1.2、三级为1.1。当反弯点不在柱的层高范围内时,柱端的弯矩设计值可直接乘以上述强柱系数。

为强柱系数,一级为1.4、二级为1.2、三级为1.1。当反弯点不在柱的层高范围内时,柱端的弯矩设计值可直接乘以上述强柱系数。

一、二、三级框架结构的底层柱下端截面的弯矩设计值,应分别乘以1.5、1.25和1.15。

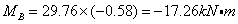

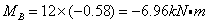

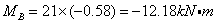

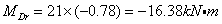

B柱的内力调整:

不需调整

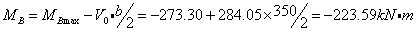

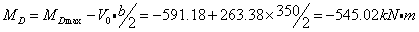

D柱的内力调整:

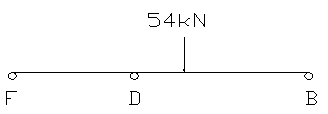

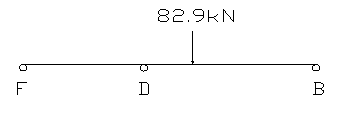

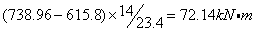

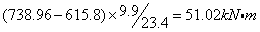

一层柱顶的弯矩设计值:

二层柱底的弯矩设计值:

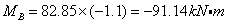

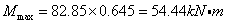

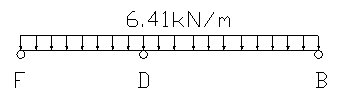

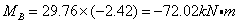

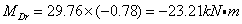

(2)BD跨:

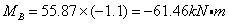

梁端负弯矩:

跨中弯矩:

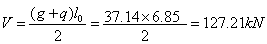

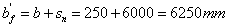

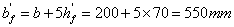

跨中按T形截面计算:

故翼缘计算宽度:

取

取

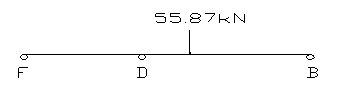

B支座边的弯矩设计值:

B支座边的弯矩设计值:

(3)两类T形截面的判别:

属于第一类T形截面

实配钢筋 4

4 28(

28( )

)

满足要求。

满足要求。

将下部跨间的4 28钢筋伸入支座,作为支座负弯矩作用下的受压钢筋

28钢筋伸入支座,作为支座负弯矩作用下的受压钢筋 ,再计算相应的钢筋

,再计算相应的钢筋 ,即支座B上部:

,即支座B上部:

说明

说明 富裕,且达不到屈服,可近似取:

富裕,且达不到屈服,可近似取:

实配钢筋 4

4 20(

20( )

)

支座D上部:

说明

说明 富裕,且达不到屈服,可近似取:

富裕,且达不到屈服,可近似取:

实配钢筋5 28(

28( )

)

8.1.2.斜截面受剪承载力计算:

箍金采用 级钢筋

级钢筋 ,则

,则

, 故按构造配置箍筋,采用

, 故按构造配置箍筋,采用 ,在梁端

,在梁端 范围内加密,

范围内加密,

8.2框架柱

8.2.1柱端弯矩调整

通过内力组合得出的设计内力还需进行调整以保证梁端的破坏先于柱端的破坏(强柱弱梁的原则)、弯曲破坏先于剪切破坏(强剪弱弯的原则)、构件的破坏先于节点的破坏(强节点弱构件的原则)。

根据“强柱弱梁”的原则进行调整的思路是:对同一节点,使其在抗震作用组合下,柱端的弯矩设计值略大于梁端的弯矩设计值或抗震设计值。

一、二、三级框架的梁柱节点处,除框支层最上层的柱上端、框架顶层和柱轴压比小于0.15者除外,柱端弯矩设计值应符合下式要求:

其中, 为节点上、下柱端截面顺时针或反时针方向组合的弯矩设计值之和,上、下柱端的弯矩设计值,一般情况可按弹性分析分配;

为节点上、下柱端截面顺时针或反时针方向组合的弯矩设计值之和,上、下柱端的弯矩设计值,一般情况可按弹性分析分配; 为节点左右梁端截面顺时针或反时针方向组合的弯矩设计值之和,节点左右梁端均为负弯矩时,绝对值较小的弯矩值应取零;

为节点左右梁端截面顺时针或反时针方向组合的弯矩设计值之和,节点左右梁端均为负弯矩时,绝对值较小的弯矩值应取零; 为强柱系数,一级为1.4、二级为1.2、三级为1.1。当反弯点不在柱的层高范围内时,柱端的弯矩设计值可直接乘以上述强柱系数。

为强柱系数,一级为1.4、二级为1.2、三级为1.1。当反弯点不在柱的层高范围内时,柱端的弯矩设计值可直接乘以上述强柱系数。

一、二、三级框架结构的底层柱下端截面的弯矩设计值,应分别乘以1.5、1.25和1.15。

以第一层梁与B轴柱结点的梁端弯矩值由内力组合表查得:

左震

左震

右震  取左震

取左震

左震

左震

右震

上下柱端弯矩值:

一层柱顶的弯矩设计值:

二层柱底的弯矩设计值:

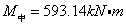

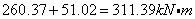

对底层柱底弯矩:

各控制截面控制内力如下:

Ⅰ—Ⅰ截面:

Ⅰ—Ⅰ截面:

Ⅱ—Ⅱ截面:

Ⅲ—Ⅲ截面:

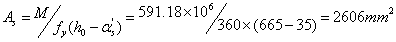

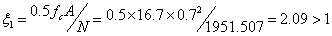

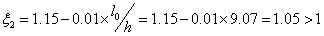

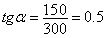

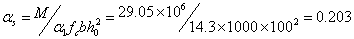

8.2.2正截面设计

具体配筋如下:

取Ⅲ—Ⅲ截面为控制截面:

1

属于大偏心受压构件。 采用对称配筋:  2

2

属于小偏心受压构件。

故按构造配筋

则按Ⅲ—Ⅲ截面组内力配置钢筋,即6 22(

22( )

)

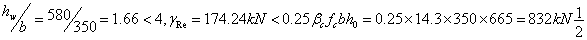

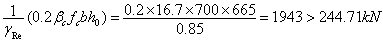

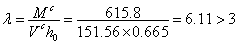

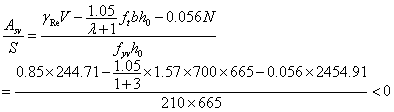

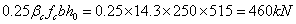

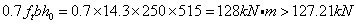

8.2.3斜截面设计:

柱端弯矩值:

满足要求。

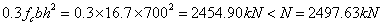

验算柱的截面尺寸:

符号要求。

符号要求。

,取

,取

故该层柱构造配置箍筋。

,查表

,查表

取

取

则

则

根据八度抗震构造要求,取加密区箍筋为 ,加密区位置及长度按规定要求确定;非加密区应满足

,加密区位置及长度按规定要求确定;非加密区应满足 ,故箍筋取

,故箍筋取

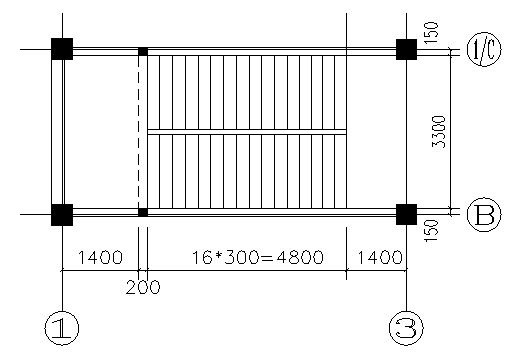

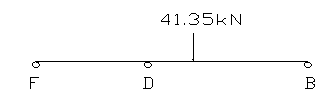

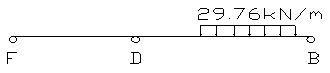

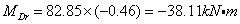

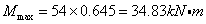

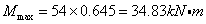

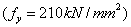

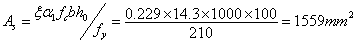

8.3次梁设计(以首层次梁为例)

8.3.1.荷载计算:

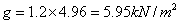

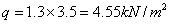

板传来的荷载:

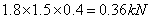

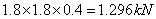

次梁自重:

抹灰自重:

合计:

活荷载设计值:

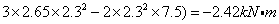

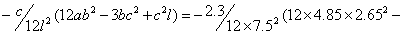

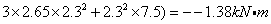

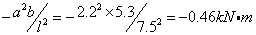

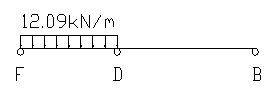

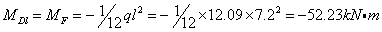

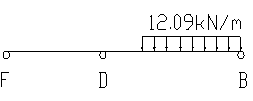

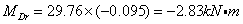

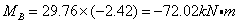

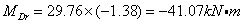

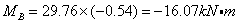

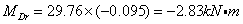

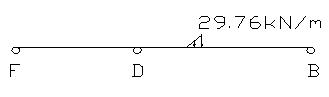

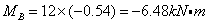

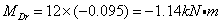

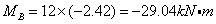

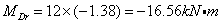

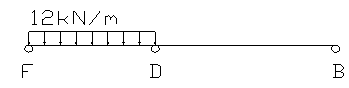

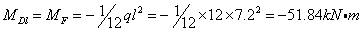

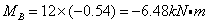

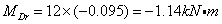

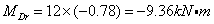

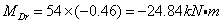

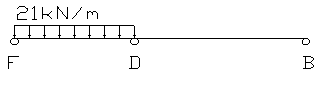

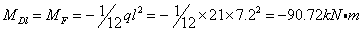

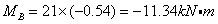

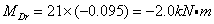

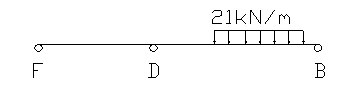

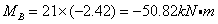

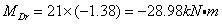

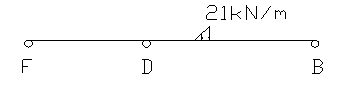

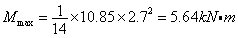

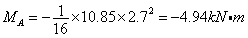

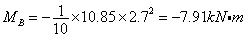

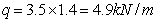

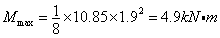

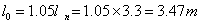

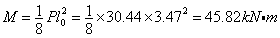

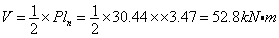

8.3.2.计算弯矩:

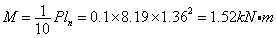

跨中:

支座:

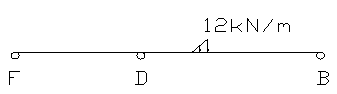

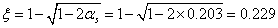

8.3.3梁正截面配筋计算:

跨中截面按T形截面计算

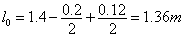

翼缘宽度的选取:按跨度考虑:

按梁间距离考虑:

取

属于第一类截面

实配钢筋

2 18(

18( )

)

满足要求。

满足要求。

支座截面:

实配钢筋

3

3 20(

20( )

)

满足要求。

满足要求。

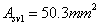

8.3.4梁斜截面配筋计算:

箍金采用 级钢筋(

级钢筋( ),则

),则

满足截面要求

,采用

,采用 ,

,

在梁端 范围内加密,

范围内加密,

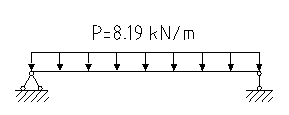

8.4板的设计

8.4.1单向板的设计:

次梁截面 ,主梁截面

,主梁截面

板的计算跨度:

计算简图:

弯矩设计值:跨中截面:

支座截面:

跨中配筋计算:

实配钢筋

支座配筋计算:

实配钢筋

走廊单向板设计:板的计算跨度:

计算简图:

弯矩设计值:跨中截面:

选配钢筋

8.4.2双向板设计:

楼面活荷载 ,恒荷载

,恒荷载 ,采用

,采用 混凝土,板中钢筋采用

混凝土,板中钢筋采用

四边固定:

四边简支:

短跨方向配筋:

选配

长跨方向配筋:

选配

支座截面:

短跨方向配筋:

选配

长跨方向配筋:

选配

8.5楼梯计算:

8.5.1梯段板设计:

梯段板荷载:

荷载种类 | 荷载标准值( ) ) |

恒荷载 | 水磨石面层 |

|

三角形踏步 |

|

混凝土斜板 |

|

板底抹灰 |

|

合计 | 6.6 |

活荷载 | 3.5 |

总荷载设计值:

板的水平计算跨度:

弯矩设计值:

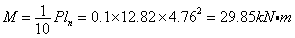

取板厚 ,约为斜长的1/30,板的倾斜角

,约为斜长的1/30,板的倾斜角

取

取 宽板带计算,板的有效高度

宽板带计算,板的有效高度

实配钢筋

,分布筋每级踏步1根

,分布筋每级踏步1根

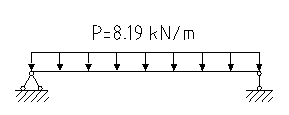

8.5.2平台板设计

1.荷载计算:

平台板荷载

荷载种类 | 荷载标准值 |

恒荷载 | 水磨石棉层 | 0.65 |

厚混凝土板 厚混凝土板

|

|

板底抹灰 |

|

小计 | 2.74 |

活荷载 | 3.5 |

总荷载设计值:

2.截面设计

平台板的计算跨度

弯矩设计值:

板的有效高度

实配钢筋

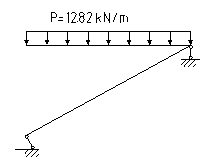

8.5.3平台梁设计

设平台梁截面尺寸为

1.荷载计算:

平台梁荷载

荷载种类 | 荷载标准值 |

恒荷载 | 梁自重 |

|

梁侧粉刷 |

|

平台板传来 |

|

梯段板传来 |

|

小计 | 14.95 |

活荷载 |

|

2.截面设计:

计算跨度:

弯矩设计值:

剪力设计值:

截面按倒L行计算,

梁的有效高度

判别属第一类T形截面

实配钢筋3 16(

16( )配置

)配置 的箍筋,

的箍筋,

则斜截面受剪承载力:

满足要求。

满足要求。

第9章 节点设计

9.1节点设计:

根据地震震害分析,不同烈度地震作用下钢筋混凝土框架节点破坏程度不同,8度地震时,部分尤其是角柱节点发生不同程度,因此对不同的框架其节点承载力和

延性要求不同,《建筑抗震设计规范》规定:对一、二级抗震等级的框架节点必须进行抗震承载力计算。

以第一层横梁与B柱相交的节点为例进行节点设计:

9.1.1节点核心区剪力设计值:

对二级框架:

:梁柱节点核心区组合的剪力设计值

:梁柱节点核心区组合的剪力设计值

:柱的计算高度,可采用节点上下反弯点之间的距离

:柱的计算高度,可采用节点上下反弯点之间的距离

:梁的截面高度

:梁的截面高度

9.1.2节点核心区截面验算:

在节点设计中首先要验算节点截面的限制条件以防止节点截面过小,核心区混凝土承受过大斜压力使节点混凝土先被压碎而破坏。

框架节点抗剪水平截面应符合如下条件:

:正交梁的影响系数。楼板为现浇,四侧各梁截面宽度不小于该柱截面宽度的1/2且正交方向梁高度不小于框架高度的3/4时,可采用1.5,其他情况采用1.0

:正交梁的影响系数。楼板为现浇,四侧各梁截面宽度不小于该柱截面宽度的1/2且正交方向梁高度不小于框架高度的3/4时,可采用1.5,其他情况采用1.0

满足要求。

满足要求。

9.1.3节点核心区截面抗剪强度计算:

其中N取二层柱底轴力

二者较小值,故取

二者较小值,故取

设节点区配筋为 ,则

,则

满足要求。

满足要求。

第10章 基础设计

10.1基础设计

基础必须有足够的刚度和稳定性,能对上部结构有可靠的嵌固作用,避免由于基础沉降和转动造成的上部应力结构复杂,防止在重大的水平力作用下,建筑物发生倾覆和滑移。因此,基础应优先采用整体性好,刚度大的基础。基础的理深一般取建筑物高度的( ),基础的形成和埋置深度确定后,设计内容还包括基础的底面尺寸和基础高度及底板配筋计算。

),基础的形成和埋置深度确定后,设计内容还包括基础的底面尺寸和基础高度及底板配筋计算。

10.1.1构造要求:

根据《砼结构构造手册》规定:(1)扩展基础砼强度等级不宜底于C15 ;钢筋砼基础的垫层宜采用C7.5的砼,其厚度为100m;(3)底板受力钢筋的最小直径不宜小于8mm,间距不宜大于200mm,也不宜小于100mm;(4)底板钢筋为构造配筋时,一般采用 ,间距为200mm的钢筋网。

,间距为200mm的钢筋网。

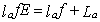

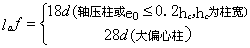

根据《砼结构构造手册》,柱下钢筋为独立基础,基础的外形尺寸:(1)轴心受压基础的底板平面采用正方形,其边长为100mm的倍数。(2)偏心受压基础的底板平面一般采用矩形,其长边与短边之比不宜大于3,其边长宜为100mm的倍数(3)基础高度应按受冲切承载力及剪切承载力和柱内的纵向钢筋在基础内的锚固长度的要求确定,一般为100mm的倍数。(4)阶梯形基础的台阶高度宜为300~500mm,阶数按下列规定采用 时为一阶;

时为一阶; 时为二阶;

时为二阶; 时为三阶。(5)阶梯形基础的外边线以外,其高度h及阶宽b一般按下述要求选用

时为三阶。(5)阶梯形基础的外边线以外,其高度h及阶宽b一般按下述要求选用 ,考虑抗震要求的柱纵向受力钢筋在基础内的锚固长度:

,考虑抗震要求的柱纵向受力钢筋在基础内的锚固长度:

,

,

对于一二级抗震等级的 ,对于三,四级不做考虑。(6)阶梯形基础边缘高度

,对于三,四级不做考虑。(6)阶梯形基础边缘高度 一般不宜小于400mm。

一般不宜小于400mm。

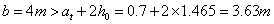

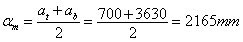

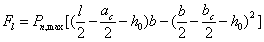

10.1.2边柱基础计算:

1、材料的选用:

(1)基础砼采用

,

, ;

;

(2)基础垫层采用c10素砼,厚度100mm,每边各伸出基础边100mm;

(3)钢筋采用一级钢筋 ;

;

2、结构形式及埋深:

(1)采用现浇阶梯形柱下独立基础。

(2)根据规范规定,基础埋深不宜小于 ,每阶高500mm,基础埋于土壤冻结深度(-1.5m)以下,则基础埋深2.55m。

,每阶高500mm,基础埋于土壤冻结深度(-1.5m)以下,则基础埋深2.55m。

(3)基础顶面高为-1.5m,基础梁取 ,基础高为1.5m。

,基础高为1.5m。

(4)地基承载力标准值为 ,持力层为中粗砂层,二类场地。

,持力层为中粗砂层,二类场地。

3、荷载计算:

由B柱内力组合值查得:离开最不利情况则:

,

,

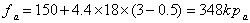

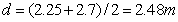

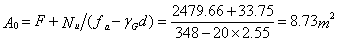

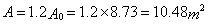

4、基础底面积计算:

(1)基底面积估算:

按中心荷载初步估计所需底面积,预估时先不考虑宽度修正。

持力层承载力特征值:

初步选择基础底面尺寸:

基础平均埋深:

由于偏心不大,基础底面积按20%增大即:

取 ,则

,则

基础底面的截面抗矩:

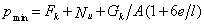

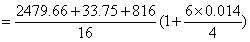

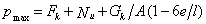

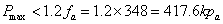

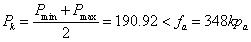

(2)验算地基承载力:

偏心距:

基底最大压力:

满足要求。

满足要求。

满足要求。

满足要求。

故基础底面积尺寸满足要求。

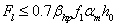

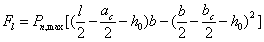

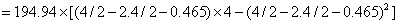

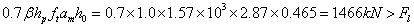

(3)基础抗冲切验算

在基础承受柱传来的轴向力时,如果沿柱周边处的基础有效高度不够,就会产生沿柱边方向斜面的冲切破坏,故冲切破坏锥体以外的地基净反力所产生的冲切力不小于切面外的抗冲能力。即:

其中:

:基础冲切破坏锥体的有效高度

:基础冲切破坏锥体的有效高度

柱边缘处:

因偏心受压 取

取

冲切力

抗冲切力:

第一变阶处:

取

冲切力

抗冲切力:

第二变阶处:

取

冲切力

抗冲切力:

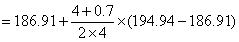

(4)配筋计算:

柱边缘截面:

第一变阶截面:

第二变阶截面:

故基底应按第一变阶截面配筋,对基础受力钢筋最小直径为10mm,间距不大于200mm,故 两个方向配筋均为第一变阶截面:

两个方向配筋均为第一变阶截面: ,实际配钢筋的面积:

,实际配钢筋的面积: 配筋如图2—19所示。

配筋如图2—19所示。

第11章 PKPM计算结果

****** PK11.EXE ******

DATA: 5/25/2007

-------总信息--------

节点总数= 27 柱子总数= 22 梁数= 14

是否规则框架= 20600 支座约束数= 5 标准截面总数= 3

活载计算信息= 1 风活载计算信息= 0 抗震等级= 2

柱砼等级= 0 梁砼等级= 0 梁柱主筋级别= 3

梁柱箍筋级别= 1 柱保护层= 35 梁保护层= 35

柱梁自重计算信息= 2 基础计算信息= 0 输出方式= 1

梁支座负弯矩调幅系数=0.85 梁惯性矩增大系数=1.20 结构重要性系数=1.00

柱计算长度考虑GB50010-2002第7.3.11-3条规定= 0

--------------节点坐标-----------------

节点号 x坐标 y坐标 节点号 x坐标 y坐标 节点号 x坐标 y坐标

( 1) 0.00 5.40 ( 2) 7.20 5.40 ( 3) 8.03 5.40

( 4) 15.53 5.40 ( 5) 22.73 5.40 ( 6) 0.00 9.90

( 7) 7.20 9.90 ( 8) 8.03 9.90 ( 9) 15.53 9.90

( 10) 22.73 9.90 ( 11) 8.03 13.20 ( 12) 15.53 13.20

( 13) 22.73 13.20 ( 14) 8.03 16.50 ( 15) 15.53 16.50

( 16) 22.73 16.50 ( 17) 8.03 19.80 ( 18) 15.53 19.80

( 19) 22.73 19.80 ( 20) 8.03 23.10 ( 21) 15.53 23.10

( 22) 22.73 23.10 ( 23) 0.00 0.00 ( 24) 7.20 0.00

( 25) 8.03 0.00 ( 26) 15.53 0.00 ( 27) 22.73 0.00

--柱杆件关联号(左为上部节点号,右为下部节点号)--

( 1) 23 1 ( 2) 24 2 ( 3) 25 3 ( 4) 26 4 ( 5) 27 5

( 6) 1 6 ( 7) 2 7 ( 8) 3 8 ( 9) 4 9 ( 10) 5 10

( 11) 8 11 ( 12) 9 12 ( 13) 10 13 ( 14) 11 14 ( 15) 12 15

( 16) 13 16 ( 17) 14 17 ( 18) 15 18 ( 19) 16 19 ( 20) 17 20

( 21) 18 21 ( 22) 19 22

--梁杆件关联号(左为左边节点号,右为右边节点号)--

( 1) 1 2 ( 2) 3 4 ( 3) 4 5 ( 4) 6 7 ( 5) 8 9

( 6) 9 10 ( 7) 11 12 ( 8) 12 13 ( 9) 14 15 ( 10) 15 16

( 11) 17 18 ( 12) 18 19 ( 13) 20 21 ( 14) 21 22

--------------支座约束信息----------------

( 1) 23111 ( 2) 24111 ( 3) 25111 ( 4) 26111 ( 5) 27111

-------------柱计算长度系数---------------

( 1) 1.00 ( 2) 1.00 ( 3) 1.00 ( 4) 1.00 ( 5) 1.00 ( 6) 1.25 ( 7) 1.25

( 8) 1.25 ( 9) 1.25 ( 10) 1.25 ( 11) 1.25 ( 12) 1.25 ( 13) 1.25 ( 14) 1.25

( 15) 1.25 ( 16) 1.25 ( 17) 1.25 ( 18) 1.25 ( 19) 1.25 ( 20) 1.25 ( 21) 1.25

( 22) 1.25

------------柱平面外计算长度--------------

( 1) 5.40 ( 2) 5.40 ( 3) 5.40 ( 4) 5.40 ( 5) 5.40 ( 6) 5.62 ( 7) 5.62

( 8) 5.62 ( 9) 5.62 ( 10) 5.62 ( 11) 4.12 ( 12) 4.12 ( 13) 4.12 ( 14) 4.12

( 15) 4.12 ( 16) 4.12 ( 17) 4.12 ( 18) 4.12 ( 19) 4.12 ( 20) 4.12 ( 21) 4.12

( 22) 4.12

--------------节点偏心值----------------

( 1) 0.00 ( 2) 0.00 ( 3) 0.00 ( 4) 0.00 ( 5) 0.00 ( 6) 0.00 ( 7) 0.00

( 8) 0.00 ( 9) 0.00 ( 10) 0.00 ( 11) 0.00 ( 12) 0.00 ( 13) 0.00 ( 14) 0.00

( 15) 0.00 ( 16) 0.00 ( 17) 0.00 ( 18) 0.00 ( 19) 0.00 ( 20) 0.00 ( 21) 0.00

( 22) 0.00 ( 23) 0.00 ( 24) 0.00 ( 25) 0.00 ( 26) 0.00 ( 27) 0.00

--------------标准截面数据----------------

( 1) 1.00 0.70 0.70

( 2) 1.00 0.50 0.50

( 3) 1.00 0.35 0.70

--------------柱截面类型号----------------

( 1) 1 ( 2) 1 ( 3) 1 ( 4) 1 ( 5) 1 ( 6) 1 ( 7) 1 ( 8) 1 ( 9) 1

( 10) 1 ( 11) 2 ( 12) 2 ( 13) 2 ( 14) 2 ( 15) 2 ( 16) 2 ( 17) 2 ( 18) 2

( 19) 2 ( 20) 2 ( 21) 2 ( 22) 2

--------------梁柱截面类型号----------------

( 1) 3 ( 2) 3 ( 3) 3 ( 4) 3 ( 5) 3 ( 6) 3 ( 7) 3 ( 8) 3 ( 9) 3

( 10) 3 ( 11) 3 ( 12) 3 ( 13) 3 ( 14) 3

------恒载计算------

节点荷载: 节点 弯矩 垂直力 水平力

1 0.00 148.40 0.00

2 0.00 81.40 0.00

3 0.00 102.50 0.00

4 0.00 140.70 0.00

5 0.00 182.10 0.00

6 0.00 97.00 0.00

7 0.00 97.00 0.00

8 0.00 165.20 0.00

9 0.00 186.40 0.00

10 0.00 159.80 0.00

11 0.00 149.60 0.00

12 0.00 186.40 0.00

13 0.00 159.80 0.00

14 0.00 149.60 0.00

15 0.00 186.40 0.00

16 0.00 159.80 0.00

17 0.00 149.60 0.00

18 0.00 186.40 0.00

19 0.00 159.80 0.00

20 0.00 112.50 0.00

21 0.00 131.30 0.00

22 0.00 122.90 0.00

0

柱间荷载 柱信息 荷载类型 荷载值 荷载参数1 荷载参数2

0

梁间荷载: 连续数 荷载个数 类型 荷载值 参数 类型 荷载值 参数

1 1 6 29.7 3.00

1 3 1 5.4 0.00 4 100.71 5.30

2 5.2 5.30

1 1 6 14.8 1.50

1 1 6 29.7 3.00

1 3 1 13.1 0.00 4 145.99 5.30

2 5.2 5.30

1 2 1 7.6 0.00 6 14.88 1.50

1 3 1 5.4 0.00 4 145.99 5.30

2 12.8 5.30

1 2 1 7.6 0.00 6 14.88 1.50

1 3 1 5.4 0.00 4 145.99 5.30

2 12.8 5.30

1 2 1 7.6 0.00 6 14.88 1.50

1 3 1 5.4 0.00 4 145.99 5.30

2 12.8 5.30

1 2 1 7.6 0.00 6 14.88 1.50

1 3 1 4.9 0.00 4 93.90 5.30

2 4.6 5.30

1 1 6 13.3 1.50

**恒载内力**

杆件号 弯矩 轴力 剪力 弯矩 轴力 剪力 杆件号 弯矩 轴力 剪力 弯矩 轴力 剪力

-- 柱(左面为柱下端,右为柱上端)--

1 -18.31 535.77 -9.81 -34.68 -469.62 9.81 2 18.31 468.77 9.81 34.68 -402.62 -9.81

3 -25.25 1664.66 -11.19 -35.20 -1598.51 11.19 4 5.31 2788.79 4.99 21.65 -2722.64 -4.99

5 8.07 1571.64 6.20 25.42 -1505.49 -6.20 6 -78.00 236.67 -40.35 -103.56 -181.55 40.35

7 78.00 236.67 40.35 103.56 -181.55 -40.35 8 -86.08 1411.90 -43.29 -108.71 -1356.78 43.29

9 43.00 2380.38 23.24 61.59 -2325.25 -23.24 10 38.49 1264.93 20.05 51.72 -1209.81 -20.05

11 -59.96 1069.93 -39.65 -70.90 -1049.31 39.65 12 32.68 1839.91 20.80 35.95 -1819.29 -20.80

13 29.20 968.74 18.86 33.03 -948.11 -18.86 14 -77.04 782.25 -46.21 -75.47 -761.62 46.21

15 40.08 1343.62 24.06 39.34 -1323.00 -24.06 16 36.95 710.00 22.15 36.15 -689.38 -22.15

17 -74.79 494.24 -45.50 -75.35 -473.62 45.50 18 38.91 848.30 23.54 38.77 -827.68 -23.54

19 36.19 450.62 21.96 36.27 -429.99 -21.96 20 -73.69 206.51 -46.03 -78.23 -185.88 46.03

21 40.51 352.74 24.41 40.05 -332.12 -24.41 22 36.06 191.21 21.62 35.30 -170.58 -21.62

-- 梁(左面为梁左端,右为梁右端)--

1 112.68 -30.53 84.55 -112.68 30.53 84.55 2 121.29 -32.09 84.11 -171.79 32.09 131.10

3 107.14 -13.84 70.46 -63.92 13.84 58.45 4 103.56 40.35 84.55 -103.56 -40.35 84.55

5 168.68 3.63 121.65 -252.41 -3.63 196.22 6 158.14 1.19 102.72 -80.92 -1.19 81.27

7 147.93 -6.56 117.46 -244.56 6.56 183.58 8 168.54 -3.29 105.69 -69.97 3.29 78.31

9 150.26 0.72 117.78 -244.47 -0.72 183.26 10 166.23 0.19 105.04 -72.34 -0.19 78.96

11 149.04 -0.54 117.51 -245.29 0.54 183.53 12 166.01 0.33 105.01 -72.33 -0.33 78.99

13 78.23 46.03 73.38 -165.34 -46.03 128.14 14 125.29 21.62 72.68 -35.30 -21.62 47.68

**恒荷载作用下的节点位移(mm)**

节点号. X向位移 Y向位移

1 -0.02 0.00

2 0.02 0.00

3 -0.12 0.00

4 -0.09 0.00

5 -0.07 0.00

6 0.02 0.00

7 -0.02 0.00

8 -0.27 0.00

9 -0.27 0.00

10 -0.27 0.00

11 -0.40 0.00

12 -0.40 0.00

13 -0.39 0.00

14 -0.50 0.00

15 -0.50 0.00

16 -0.50 0.00

17 -0.61 0.00

18 -0.61 0.00

19 -0.61 0.00

20 -0.64 0.00

21 -0.68 0.00

22 -0.70 0.00

------活载计算------

节点荷载: 节点 弯矩 垂直力 水平力

1 0.00 31.50 0.00

2 0.00 31.50 0.00

3 0.00 38.90 0.00

4 0.00 64.50 0.00

5 0.00 45.70 0.00

6 0.00 31.50 0.00

7 0.00 31.50 0.00

8 0.00 61.60 0.00

9 0.00 88.50 0.00

10 0.00 69.70 0.00

11 0.00 50.40 0.00

12 0.00 70.10 0.00

13 0.00 56.70 0.00

14 0.00 50.40 0.00

15 0.00 70.10 0.00

16 0.00 56.70 0.00

17 0.00 50.40 0.00

18 0.00 70.10 0.00

19 0.00 56.70 0.00

20 0.00 40.30 0.00

21 0.00 56.10 0.00

22 0.00 45.30 0.00

0

柱间荷载 柱信息 荷载类型 荷载值 荷载参数1 荷载参数2

0

梁间荷载: 连续数 荷载个数 类型 荷载值 参数 类型 荷载值 参数

1 1 6 21.0 3.00

1 3 1 3.8 0.00 4 51.11 5.30

2 3.6 5.30

1 1 6 10.5 1.50

1 1 6 21.0 3.00

1 3 1 6.3 0.00 4 72.20 5.30

2 3.6 5.30

1 2 1 2.5 0.00 6 10.50 1.50

1 3 1 5.2 0.00 4 57.41 5.30

2 2.6 5.30

1 2 1 2.5 0.00 6 7.50 1.50

1 3 1 5.2 0.00 4 57.41 5.30

2 2.6 5.30

1 2 1 2.5 0.00 6 7.50 1.50

1 3 1 5.2 0.00 4 57.41 5.30

2 2.6 5.30

1 2 1 2.5 0.00 6 7.50 1.50

1 3 1 4.2 0.00 4 45.93 5.30

2 2.1 5.30

1 2 1 2.0 0.00 6 6.00 1.50

**活荷载标准值作用下的节点位移(mm)**

节点号. X向位移 Y向位移

1 -0.01 0.05

2 0.01 0.05

3 -0.06 0.20

4 -0.05 0.35

5 -0.04 0.18

6 0.01 0.08

7 -0.01 0.08

8 -0.15 0.34

9 -0.15 0.60

10 -0.15 0.31

11 -0.23 0.49

12 -0.23 0.87

13 -0.22 0.44

14 -0.29 0.60

15 -0.29 1.07

16 -0.29 0.55

17 -0.37 0.67

18 -0.36 1.19

19 -0.36 0.61

20 -0.40 0.70

21 -0.42 1.25

22 -0.44 0.64

-----------地震力计算------------

计算振型数= 1 地震烈度= 8.00

场地土分类= 2.00 附加重量的质点数= 0

地震设计分组= 1 周期折减系数= 1.00

地震力计算方式= 0 阻尼系数= 0.05

**左地震方向计算**

振动质点号: 1 3 6 8 11 14 17

振动质点号: 20

振动质点质量: 595.767 1105.558 493.817 1345.376 1217.043 1217.043 1217.043 858.953

水平地震标准值作用底层剪力: 332.506

底层最小地震剪力: 257.619

各质点地震力调整系数: 1.000

地震力调整后剪重比: 0.041

第 1振动周期T= 1.1539

质点特征向量值: 0.000 0.229 0.000 0.494 0.695 0.847 0.949 1.000

质点水平地震力: 0.000 17.526 0.000 45.936 58.505 71.289 79.868 59.383

***各结构节点变位***

( 1) 0.000 ( 2) 0.000 ( 3) 0.005 ( 4) 0.005 ( 5) 0.005 ( 6) 0.000 ( 7) 0.000 ( 8) 0.011 ( 9) 0.011

(10) 0.011 (11) 0.016 (12) 0.016 (13) 0.016 (14) 0.019 (15) 0.019 (16) 0.019 (17) 0.022 (18) 0.022

(19) 0.022 (20) 0.023 (21) 0.023 (22) 0.023 (23) 0.000 (24) 0.000 (25) 0.000 (26) 0.000 (27) 0.000

杆件号 弯矩 轴力 剪力 弯矩 轴力 剪力 杆件号 弯矩 轴力 剪力 弯矩 轴力 剪力

-- 柱(左面为柱下端,右为柱上端)--

1 0.00 0.00 0.00 0.00 0.00 0.00 2 0.00 0.00 0.00 0.00 0.00 0.00

3 406.99 -274.81 101.05 138.69 274.81 -101.05 4 458.51 -18.98 129.24 239.41 18.98 -129.24

5 409.17 293.79 102.21 142.75 -293.79 -102.21 6 0.00 0.00 0.00 0.00 0.00 0.00

7 0.00 0.00 0.00 0.00 0.00 0.00 8 168.28 -195.64 77.68 181.30 195.64 -77.68

9 344.28 -12.85 156.86 361.59 12.85 -156.86 10 174.42 208.50 80.43 187.52 -208.50 -80.43

11 108.78 -121.18 73.23 132.89 121.18 -73.23 12 184.03 -7.29 120.94 215.06 7.29 -120.94

13 111.45 128.47 74.87 135.63 -128.47 -74.87 14 78.96 -68.46 55.08 102.79 68.46 -55.08

15 156.69 -3.74 99.13 170.43 3.74 -99.13 16 81.24 72.21 56.33 104.66 -72.21 -56.33

17 48.83 -30.52 37.08 73.55 30.52 -37.08 18 98.32 -1.35 64.46 114.41 1.35 -64.46

19 50.02 31.86 37.70 74.40 -31.86 -37.70 20 14.41 -8.44 14.81 34.47 8.44 -14.81

21 41.60 -0.19 29.82 56.81 0.19 -29.82 22 14.54 8.63 14.75 34.14 -8.63 -14.75

-- 梁(左面为梁左端,右为梁右端)--

1 0.00 0.00 0.00 0.00 0.00 0.00 2 -306.97 -17.52 -79.16 -286.76 17.52 79.16

3 -296.92 15.93 -85.29 -317.17 -15.93 85.29 4 0.00 0.00 0.00 0.00 0.00 0.00

5 -290.08 10.86 -74.47 -268.40 -10.86 74.47 6 -277.22 -9.75 -80.03 -298.97 9.75 80.03

7 -211.85 1.34 -52.71 -183.50 -1.34 52.71 8 -188.24 -0.96 -56.26 -216.87 0.96 56.26

9 -151.61 5.77 -37.95 -132.98 -5.77 37.95 10 -135.77 -5.13 -40.34 -154.68 5.13 40.34

11 -87.96 4.35 -22.08 -77.64 -4.35 22.08 12 -78.37 -3.67 -23.24 -88.94 3.67 23.24

13 -34.47 4.98 -8.44 -28.83 -4.98 8.44 14 -27.98 -5.04 -8.63 -34.14 5.04 8.63

**右地震方向计算**

振动质点号: 2 5 7 10 13 16 19

振动质点号: 22

振动质点质量: 595.767 1105.558 493.817 1345.376 1217.043 1217.043 1217.043 858.953

水平地震标准值作用底层剪力: 332.529

底层最小地震剪力: 257.619

各质点地震力调整系数: 1.000

地震力调整后剪重比: 0.041

第 1振动周期T= 1.1539

质点特征向量值: 0.000 0.229 0.000 0.494 0.695 0.847 0.949 1.000

质点水平地震力: 0.000 17.535 0.000 45.933 58.508 71.292 79.872 59.389

***各结构节点变位***

( 1) 0.000 ( 2) 0.000 ( 3)-0.005 ( 4)-0.005 ( 5)-0.005 ( 6) 0.000 ( 7) 0.000 ( 8)-0.011 ( 9)-0.011

(10)-0.011 (11)-0.016 (12)-0.016 (13)-0.016 (14)-0.019 (15)-0.019 (16)-0.019 (17)-0.022 (18)-0.022

(19)-0.022 (20)-0.023 (21)-0.023 (22)-0.023 (23) 0.000 (24) 0.000 (25) 0.000 (26) 0.000 (27) 0.000

杆件号 弯矩 轴力 剪力 弯矩 轴力 剪力 杆件号 弯矩 轴力 剪力 弯矩 轴力 剪力

-- 柱(左面为柱下端,右为柱上端)--

1 0.00 0.00 0.00 0.00 0.00 0.00 2 0.00 0.00 0.00 0.00 0.00 0.00

3 -407.02 274.82 -101.06 -138.70 -274.82 101.06 4 -458.54 18.98 -129.25 -239.42 -18.98 129.25

5 -409.20 -293.81 -102.21 -142.76 293.81 102.21 6 0.00 0.00 0.00 0.00 0.00 0.00

7 0.00 0.00 0.00 0.00 0.00 0.00 8 -168.29 195.66 -77.69 -181.31 -195.66 77.69

9 -344.29 12.85 -156.87 -361.61 -12.85 156.87 10 -174.43 -208.51 -80.44 -187.53 208.51 80.44

11 -108.79 121.19 -73.24 -132.90 -121.19 73.24 12 -184.04 7.29 -120.94 -215.07 -7.29 120.94

13 -111.46 -128.48 -74.88 -135.64 128.48 74.88 14 -78.97 68.47 -55.08 -102.79 -68.47 55.08

15 -156.70 3.74 -99.13 -170.45 -3.74 99.13 16 -81.24 -72.21 -56.34 -104.67 72.21 56.34

17 -48.83 30.52 -37.09 -73.55 -30.52 37.09 18 -98.32 1.35 -64.47 -114.42 -1.35 64.47

19 -50.02 -31.87 -37.71 -74.41 31.87 37.71 20 -14.41 8.44 -14.81 -34.47 -8.44 14.81

21 -41.60 0.19 -29.82 -56.81 -0.19 29.82 22 -14.54 -8.63 -14.75 -34.14 8.63 14.75

-- 梁(左面为梁左端,右为梁右端)--

1 0.00 0.00 0.00 0.00 0.00 0.00 2 306.98 17.53 79.17 286.78 -17.53 -79.17

3 296.94 -15.93 85.30 317.19 15.93 -85.30 4 0.00 0.00 0.00 0.00 0.00 0.00

5 290.10 -10.86 74.47 268.42 10.86 -74.47 6 277.24 9.75 80.03 298.98 -9.75 -80.03

7 211.86 -1.34 52.72 183.51 1.34 -52.72 8 188.25 0.96 56.27 216.88 -0.96 -56.27

9 151.62 -5.77 37.95 132.99 5.77 -37.95 10 135.78 5.13 40.34 154.69 -5.13 -40.34

11 87.96 -4.35 22.08 77.64 4.35 -22.08 12 78.38 3.67 23.24 88.95 -3.67 -23.24

13 34.47 -4.98 8.44 28.83 4.98 -8.44 14 27.98 5.04 8.63 34.14 -5.04 -8.63

***组合与配筋***

柱 1 ( B= 0.700, H= 0.700, Lx= 5.40, Ly= 5.40 Rc=35 )

NO 1 As= 0. M= -21.97 N= 642.92 NO 1 As= 0. M= -41.62 N= -563.54

Asmin= 1715.

No 51 Vc= 25.29 N= 707.13 ASV= 199. ASV0= 0.

No 53 N= 654.26 轴压比= 0.080

柱 2 ( B= 0.700, H= 0.700, Lx= 5.40, Ly= 5.40 Rc=35 )

NO 1 As= 0. M= 21.97 N= 562.52 NO 1 As= 0. M= 41.62 N= -483.14

Asmin= 1715.

No 49 Vc= 25.29 N= 626.73 ASV= 199. ASV0= 0.

No 53 N= 573.86 轴压比= 0.070

柱 3 ( B= 0.700, H= 0.700, Lx= 5.40, Ly= 5.40 Rc=35 )

NO 56 As= 1097. M= 504.10 N= 1303.36 NO 1 As= 0. M= -42.24 N= -1918.21

Asmin= 1715.

No 51 Vc= 224.92 N= 2660.52 ASV= 199. ASV0= 0.

No 53 N= 2614.65 轴压比= 0.319

柱 4 ( B= 0.700, H= 0.700, Lx= 5.40, Ly= 5.40 Rc=35 )

NO 56 As= 685. M= 601.41 N= 2764.12 NO 1 As= 0. M= 25.99 N= -3267.17

Asmin= 1715.

No 49 Vc= 270.69 N= 3483.62 ASV= 224. ASV0= 0.

No 53 N= 3894.78 轴压比= 0.475

柱 5 ( B= 0.700, H= 0.700, Lx= 5.40, Ly= 5.40 Rc=35 )

NO 56 As= 1199. M= -525.40 N= 1182.08 NO 1 As= 0. M= 30.51 N= -1806.59

Asmin= 1715.

No 49 Vc= 216.06 N= 2556.69 ASV= 199. ASV0= 0.

No 53 N= 2502.59 轴压比= 0.305

柱 6 ( B= 0.700, H= 0.700, Lx= 5.62, Ly= 5.62 Rc=35 )

NO 14 As= 243. M= -133.80 N= 283.99 NO 23 As= 572. M= -204.20 N= -279.66

Asmin= 1715.

No 51 Vc= 88.88 N= 329.34 ASV= 199. ASV0= 0.

No 53 N= 263.22 轴压比= 0.032

柱 7 ( B= 0.700, H= 0.700, Lx= 5.62, Ly= 5.62 Rc=35 )

NO 31 As= 243. M= 133.80 N= 283.99 NO 19 As= 572. M= 204.20 N= -279.66

Asmin= 1715.

No 49 Vc= 88.88 N= 329.34 ASV= 199. ASV0= 0.

No 53 N= 263.22 轴压比= 0.032

柱 8 ( B= 0.700, H= 0.700, Lx= 5.62, Ly= 5.62 Rc=35 )

NO 1 As= 0. M= -103.30 N= 1694.28 NO 52 As= 171. M= -377.76 N= -1707.85

Asmin= 1715.

No 51 Vc= 241.94 N= 1998.55 ASV= 199. ASV0= 0.

No 53 N= 2174.17 轴压比= 0.265

柱 9 ( B= 0.700, H= 0.700, Lx= 5.62, Ly= 5.62 Rc=35 )

NO 50 As= 339. M= 515.61 N= 2489.56 NO 50 As= 514. M= 567.74 N= -2611.47

Asmin= 1715.

No 49 Vc= 357.01 N= 3137.10 ASV= 199. ASV0= 0.

No 53 N= 3319.61 轴压比= 0.405

柱 10 ( B= 0.700, H= 0.700, Lx= 5.62, Ly= 5.62 Rc=35 )

NO 1 As= 0. M= 46.19 N= 1517.92 NO 50 As= 15. M= 317.52 N= -1547.21

Asmin= 1715.

No 49 Vc= 199.57 N= 1868.58 ASV= 199. ASV0= 0.

No 53 N= 1991.86 轴压比= 0.243

柱 11 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 51 As= 414. M= -234.26 N= 1522.25 NO 51 As= 734. M= -281.74 N= -1498.40

Asmin= 875.

No 51 Vc= 224.89 N= 1498.40 ASV= 135. ASV0= 29.

No 53 N= 1638.21 轴压比= 0.392

柱 12 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 49 As= 718. M= 300.79 N= 2316.12 NO 49 As= 1018. M= 346.52 N= -2437.96

Asmin= 875.

No 49 Vc= 282.31 N= 2437.96 ASV= 186. ASV0= 80.

No 53 N= 2580.28 轴压比= 0.617

柱 13 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 50 As= 239. M= 185.45 N= 1182.32 NO 50 As= 493. M= 222.43 N= -1161.69

Asmin= 875.

No 49 Vc= 185.55 N= 1385.38 ASV= 135. ASV0= 0.

No 53 N= 1509.07 轴压比= 0.361

柱 14 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 51 As= 509. M= -220.31 N= 1106.67 NO 51 As= 732. M= -249.80 N= -1056.65

Asmin= 875.

No 51 Vc= 204.62 N= 1056.65 ASV= 135. ASV0= 22.

No 53 N= 1167.26 轴压比= 0.279

柱 15 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 50 As= 649. M= 264.10 N= 1416.19 NO 50 As= 738. M= 281.65 N= -1486.17

Asmin= 875.

No 49 Vc= 248.55 N= 1784.38 ASV= 152. ASV0= 50.

No 53 N= 1881.52 轴压比= 0.450

柱 16 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 50 As= 261. M= 156.41 N= 833.40 NO 50 As= 472. M= 186.49 N= -815.01

Asmin= 875.

No 49 Vc= 157.54 N= 981.31 ASV= 135. ASV0= 0.

No 53 N= 1073.24 轴压比= 0.257

柱 17 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 51 As= 523. M= -179.25 N= 683.42 NO 51 As= 773. M= -211.99 N= -639.42

Asmin= 875.

No 51 Vc= 170.22 N= 639.42 ASV= 135. ASV0= 16.

No 53 N= 714.33 轴压比= 0.171

柱 18 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 50 As= 425. M= 187.37 N= 891.42 NO 50 As= 537. M= 208.28 N= -930.10

Asmin= 875.

No 50 Vc= 172.59 N= 930.10 ASV= 135. ASV0= 1.

No 53 N= 1184.59 轴压比= 0.283

柱 19 ( B= 0.500, H= 0.500, Lx= 4.12, Ly= 4.12 Rc=35 )

NO 50 As= 231. M= 115.87 N= 508.89 NO 50 As= 443. M= 147.77 N= -490.50

Asmin= 875.

No 49 Vc= 122.97 N= 602.39 ASV= 135. ASV0= 0.

No 53 N= 656.38 轴压比= 0.157

柱 20 ( B= 0.500, H= 0.500, Lx= 4.13, Ly= 4.12 Rc=35 )

NO 23 As= 667. M= -154.08 N= 298.58 NO 8 As= 805. M= -170.51 N= -277.92

Asmin= 875.

No 51 Vc= 132.82 N= 280.54 ASV= 135. ASV0= 0.

No 53 N= 281.55 轴压比= 0.067

柱 21 ( B= 0.500, H= 0.500, Lx= 4.13, Ly= 4.12 Rc=35 )

NO 49 As= 323. M= 127.86 N= 487.07 NO 49 As= 461. M= 146.82 N= -462.61

Asmin= 875.

No 49 Vc= 119.84 N= 462.61 ASV= 135. ASV0= 0.

No 53 N= 486.78 轴压比= 0.116

柱 22 ( B= 0.500, H= 0.500, Lx= 4.13, Ly= 4.12 Rc=35 )

NO 19 As= 259. M= 88.24 N= 262.56 NO 49 As= 437. M= 109.17 N= -233.60

Asmin= 875.

No 49 Vc= 81.77 N= 233.60 ASV= 135. ASV0= 0.

No 53 N= 260.57 轴压比= 0.062

梁 1 ( B= 0.350, H= 0.700, L= 7.20 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 0.00 0.00 0.00 -75.42 -135.14 -173.46 -186.47 -173.40 -135.03 -75.25 0.00 0.00 0.00

As(1)= 735. 0. 0. 327. 595. 771. 832. 771. 594. 326. 0. 0. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 188.80 100.47 22.39 0.00 0.00 0.00 0.00 0.00 0.00 0.00 22.61 100.75 188.80

As(1)= 843. 438. 96. 0. 0. 0. 0. 0. 0. 0. 97. 440. 843.

As(2)= 843. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 843.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 163.25 NO 5 Vr= 163.25 NO 8 Asv/s= 0.67 Asmin= 612. Umaxb= 0.003 Umaxt= 0.003

Umaxb=0.003 Umaxt=0.003 V1.5h= 120.84 Asv1.5h/s= 0.00

梁 2 ( B= 0.350, H= 0.700, L= 7.50 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= -298.58 -267.24 -257.10 -245.49 -226.90 -198.68 -187.79 -210.17 -247.46 -269.35 -249.28 -237.90 -232.41

As(1)= 1009. 898. 862. 821. 756. 678. 838. 944. 993. 905. 834. 794. 775.

As(2)= 1009. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 775.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 557.30 398.87 282.92 180.05 85.83 0.00 0.00 0.00 0.00 79.45 229.95 401.17 592.05

As(1)= 1999. 1378. 953. 594. 278. 0. 0. 0. 0. 257. 767. 1387. 2143.

As(2)= 1999. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 2143.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 229.21 NO 27 Vr= 297.33 NO 29 Asv/s= 0.85 Asmin= 612. Umaxb= 0.004 Umaxt= 0.009

Umaxb=0.004 Umaxt=0.009 V1.5h= 226.57 Asv1.5h/s= 1.04

梁 3 ( B= 0.350, H= 0.700, L= 7.20 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= -301.04 -261.86 -232.17 -197.95 -158.87 -110.72 -116.28 -166.46 -218.94 -260.07 -289.93 -316.18 -362.83

As(1)= 1018. 879. 774. 656. 522. 468. 509. 548. 728. 872. 978. 1073. 1243.

As(2)= 1018. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1243.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 524.87 384.60 265.96 161.78 69.16 0.00 0.00 23.96 97.86 179.33 268.31 367.32 501.34

As(1)= 1868. 1324. 893. 532. 224. 0. 0. 77. 318. 592. 901. 1260. 1774.

As(2)= 1868. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1774.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 215.85 NO 27 Vr= 200.49 NO 29 Asv/s= 0.67 Asmin= 612. Umaxb= 0.005 Umaxt= 0.008

Umaxb=0.005 Umaxt=0.008 V1.5h= 150.50 Asv1.5h/s= 0.15

梁 4 ( B= 0.350, H= 0.700, L= 7.20 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 0.00 0.00 -14.03 -90.51 -150.29 -188.66 -201.73 -188.71 -150.39 -90.67 -14.24 0.00 0.00

As(1)= 735. 0. 60. 394. 664. 842. 904. 842. 665. 395. 61. 0. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 173.57 85.48 8.58 0.00 0.00 0.00 0.00 0.00 0.00 0.00 8.37 85.22 173.57

As(1)= 772. 371. 37. 0. 0. 0. 0. 0. 0. 0. 36. 370. 772.

As(2)= 772. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 772.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 163.26 NO 5 Vr= 163.26 NO 8 Asv/s= 0.67 Asmin= 612. Umaxb= 0.004 Umaxt= 0.003

Umaxb=0.004 Umaxt=0.003 V1.5h= 120.83 Asv1.5h/s= 0.00

梁 5 ( B= 0.350, H= 0.700, L= 7.50 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= -237.78 -226.29 -243.49 -259.90 -265.02 -256.33 -277.21 -309.66 -325.17 -301.58 -238.02 -185.94 -142.68

As(1)= 794. 754. 814. 872. 890. 1028. 1269. 1431. 1510. 1060. 795. 614. 735.

As(2)= 794. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 595.95 401.87 266.76 151.86 48.28 0.00 0.00 0.00 0.00 17.14 203.00 419.45 667.48

As(1)= 2159. 1389. 896. 499. 155. 0. 0. 0. 0. 55. 673. 1456. 2465.

As(2)= 2159. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 2604.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 277.60 NO 27 Vr= 385.26 NO 29 Asv/s= 1.33 Asmin= 612. Umaxb= 0.006 Umaxt= 0.010

Umaxb=0.006 Umaxt=0.010 V1.5h= 294.81 Asv1.5h/s= 0.77

梁 6 ( B= 0.350, H= 0.700, L= 7.20 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= -235.38 -210.28 -200.03 -182.06 -158.88 -141.37 -154.96 -194.73 -239.89 -269.87 -284.73 -292.89 -327.41

As(1)= 785. 698. 663. 601. 522. 623. 686. 661. 801. 907. 960. 989. 1114.

As(2)= 785. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1114.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 562.24 393.22 258.82 143.68 45.02 0.00 0.00 0.21 71.20 152.50 244.07 348.57 501.60

As(1)= 2019. 1357. 868. 471. 145. 0. 0. 1. 230. 501. 816. 1191. 1775.

As(2)= 2019. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1775.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 254.68 NO 27 Vr= 227.26 NO 29 Asv/s= 0.67 Asmin= 612. Umaxb= 0.005 Umaxt= 0.008

Umaxb=0.005 Umaxt=0.008 V1.5h= 166.02 Asv1.5h/s= 0.33

梁 7 ( B= 0.350, H= 0.700, L= 7.50 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= -154.27 -162.58 -192.70 -223.52 -241.03 -245.24 -267.83 -295.41 -307.22 -238.12 -157.57 -92.28 -41.41

As(1)= 735. 535. 638. 744. 805. 1012. 1222. 1359. 1419. 996. 518. 300. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 464.60 300.62 186.76 93.78 10.36 0.00 0.00 0.00 0.00 0.00 129.48 318.02 537.78

As(1)= 1629. 1017. 617. 305. 33. 0. 0. 0. 0. 0. 423. 1079. 1920.

As(2)= 1629. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1920.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 238.16 NO 27 Vr= 332.42 NO 29 Asv/s= 1.04 Asmin= 612. Umaxb= 0.006 Umaxt= 0.008

Umaxb=0.006 Umaxt=0.008 V1.5h= 273.52 Asv1.5h/s= 0.52

梁 8 ( B= 0.350, H= 0.700, L= 7.20 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= -113.81 -104.46 -114.29 -115.29 -112.50 -133.50 -147.54 -179.53 -208.68 -223.30 -223.44 -215.28 -229.74

As(1)= 735. 340. 373. 376. 445. 587. 651. 636. 693. 743. 744. 716. 766.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 766.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 452.59 298.91 184.27 87.58 7.51 0.00 0.00 0.00 36.45 97.67 169.16 252.21 378.48

As(1)= 1583. 1011. 609. 284. 24. 0. 0. 0. 117. 317. 557. 844. 1302.

As(2)= 1583. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1302.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 222.49 NO 27 Vr= 188.36 NO 29 Asv/s= 0.67 Asmin= 612. Umaxb= 0.003 Umaxt= 0.006

Umaxb=0.003 Umaxt=0.006 V1.5h= 139.00 Asv1.5h/s= 0.02

梁 9 ( B= 0.350, H= 0.700, L= 7.50 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= -74.75 -93.65 -135.71 -178.99 -208.97 -225.64 -267.43 -295.81 -308.43 -223.24 -115.25 -38.23 0.00

As(1)= 735. 304. 444. 591. 724. 1006. 1220. 1361. 1425. 1006. 376. 123. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 390.89 236.71 134.28 53.14 0.00 0.00 0.00 0.00 0.00 0.00 86.94 262.84 472.47

As(1)= 1348. 790. 439. 171. 0. 0. 0. 0. 0. 0. 282. 882. 1724.

As(2)= 1348. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1724.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 220.09 NO 27 Vr= 322.02 NO 8 Asv/s= 0.92 Asmin= 612. Umaxb= 0.006 Umaxt= 0.007

Umaxb=0.006 Umaxt=0.007 V1.5h= 272.48 Asv1.5h/s= 0.51

梁 10 ( B= 0.350, H= 0.700, L= 7.20 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= -49.92 -50.17 -72.08 -85.33 -104.83 -135.26 -148.26 -160.41 -176.47 -177.99 -165.04 -144.29 -147.43

As(1)= 735. 162. 233. 277. 458. 595. 655. 635. 582. 587. 543. 473. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 382.60 239.47 137.92 54.71 0.00 0.00 0.00 0.00 6.16 55.30 114.71 186.05 302.20

As(1)= 1317. 800. 452. 176. 0. 0. 0. 0. 20. 178. 374. 615. 1022.

As(2)= 1317. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1022.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 201.17 NO 27 Vr= 169.23 NO 29 Asv/s= 0.67 Asmin= 612. Umaxb= 0.003 Umaxt= 0.005

Umaxb=0.003 Umaxt=0.005 V1.5h= 120.45 Asv1.5h/s= 0.00

梁 11 ( B= 0.350, H= 0.700, L= 7.50 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 0.00 -23.33 -78.37 -134.67 -177.68 -222.90 -267.63 -296.60 -309.80 -225.18 -67.92 0.00 0.00

As(1)= 735. 75. 254. 441. 720. 1004. 1221. 1365. 1432. 1015. 236. 0. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 308.96 165.38 76.34 8.33 0.00 0.00 0.00 0.00 0.00 0.00 40.11 202.84 401.54

As(1)= 1142. 549. 247. 27. 0. 0. 0. 0. 0. 0. 129. 673. 1731.

As(2)= 1142. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1731.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 211.03 NO 5 Vr= 322.54 NO 8 Asv/s= 0.80 Asmin= 612. Umaxb= 0.006 Umaxt= 0.007

Umaxb=0.006 Umaxt=0.007 V1.5h= 271.95 Asv1.5h/s= 0.50

梁 12 ( B= 0.350, H= 0.700, L= 7.20 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 0.00 0.00 -23.65 -60.59 -107.40 -136.80 -148.78 -143.34 -143.76 -131.49 -104.75 -70.54 -62.40

As(1)= 735. 0. 76. 262. 469. 602. 657. 632. 530. 430. 341. 228. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 308.11 175.64 87.88 18.74 0.00 0.00 0.00 0.00 0.00 9.49 55.44 113.20 218.71

As(1)= 1162. 604. 300. 68. 0. 0. 0. 0. 0. 30. 179. 369. 735.

As(2)= 1162. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 179.11 NO 5 Vr= 147.81 NO 8 Asv/s= 0.67 Asmin= 612. Umaxb= 0.003 Umaxt= 0.005

Umaxb=0.003 Umaxt=0.005 V1.5h= 103.79 Asv1.5h/s= 0.00

梁 13 ( B= 0.350, H= 0.700, L= 7.50 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 0.00 -6.55 -50.66 -92.22 -135.43 -176.20 -206.16 -225.29 -233.61 -174.05 -53.54 0.00 0.00

As(1)= 735. 21. 163. 364. 596. 784. 925. 1016. 1056. 774. 231. 0. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 152.52 65.39 17.01 0.00 0.00 0.00 0.00 0.00 0.00 0.00 11.71 106.21 264.58

As(1)= 735. 263. 54. 0. 0. 0. 0. 0. 0. 0. 50. 445. 1206.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 1206.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 142.92 NO 5 Vr= 237.49 NO 8 Asv/s= 0.67 Asmin= 612. Umaxb= 0.004 Umaxt= 0.005

Umaxb=0.004 Umaxt=0.005 V1.5h= 190.67 Asv1.5h/s= 0.00

梁 14 ( B= 0.350, H= 0.700, L= 7.20 Rc=30 )

梁下部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 0.00 0.00 -1.40 -43.72 -79.37 -102.55 -113.28 -111.55 -97.36 -82.37 -59.92 -30.27 -20.43

As(1)= 735. 0. 6. 188. 344. 448. 496. 488. 424. 306. 193. 97. 735.

As(2)= 735. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

梁上部截面 1 2 3 4 5 6 7 8 9 10 11 12 13

M= 204.71 116.83 68.24 27.36 0.00 0.00 0.00 0.00 0.00 0.00 8.38 37.78 99.45

As(1)= 918. 512. 295. 117. 0. 0. 0. 0. 0. 0. 27. 121. 735.

As(2)= 918. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 735.

Asc = 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

Vl= 132.01 NO 5 Vr= 98.49 NO 8 Asv/s= 0.67 Asmin= 612. Umaxb= 0.003 Umaxt= 0.004

Umaxb=0.003 Umaxt=0.004 V1.5h= 77.12 Asv1.5h/s= 0.00

------------PK1 计算终止---------------

第12章 参考资料

1 《建筑结构荷载规范》GB50009—2001

2 《混凝土结构设计规范》GB50010—2002

3 《建筑抗震设计规范》GB50011—2001

4 《土木工程施工教科书》

第13章 外文翻译

Project application of the high-performance concrete of fly ash

[The summary ]

Every performance of this text to high-performance concrete of fly ash has done detailed research, and to the concrete respectively to person who mix of fly ash Kinds of influence of performance and fly ash concrete some questions that should notice carry on analysis and discussion in not constructing.

1. Summary

Fly ash, as a kind of industrial waste material, resources are abundant , cheap, and contain a large amount of active composition , it is modern concrete Central Africa A often important component part . The high-quality fly ash is applied to the concrete rationally , not only can replace the cement partly , save the fabrication cost of the project, And, its peculiar performance can be used in the concrete of various kinds of instructions for use very effectively, improve the performance of the concrete, It is the ideal in the high-performance concrete that admixes the material . Among it is at concrete not modern, whose name is already with cement in fly ash, collect material , water , admixture and Kind is important, become a component part in concrete. Fly ash high-performance concrete regard durability as main goal go on design mix Congeal the soil . It regards excellent durability (instead of the high strength) as the main characteristic , that is to say, concrete capital of any grade of intensity Can make into the high durability concrete . In order to reach high durability, the performance that the fly ash concrete should possess is: Mixing the state newly well Work,namely, without emanating, secreting by water, so that shaping the even , closely knit by mobility, harden not shrinking subsiding early water and Water shrink light, warm to rise low, harden course is it dwindle to do, in order to reach having the initial crack, the permeability after hardenning is low.

2. " function " and " effect " of the fly ash are fly ash material technology and application foundation of the project.

Mix and add the powder of the concrete Coal ash, in conformity with understanding that the function of the fly ash is made overallly, by " volcanic ash react " and " economic component part" general to fly ash originally Read , expand technological consciousness of " fly ash effect " to , make fly ash function can serve performance of concrete improve with quality raising better. The role in concrete of fly ash has the following several points:

(1) . Shape effect: It is spongy vitreous body , little pearl of silicate glass of aluminium that the main mineral of the fly ash makes up , smooth the body surface of these spherical glass, the grain size is thin, the quality is pre-pressing, inside smaller than the surface area, the strength of absorbing to water is small, this line of physical characteristics, reduce concrete rub obstruction inside , favorable to improvement , concrete of mobility not merely; And, have " reducing water " function in various degree on the concrete;

(2) . Active effect: The active composition SiO2 of the fly ash and water result of AI2O3 and cement react in a situation that there is water, producing water silicic acid calcium (C-S-H ) and water sour calcium (C-A-S-H ) of sulphur aluminium, these responses nearly all go on in the grout hole, water that produce result pack , cut apart the heavy original hole , make the hole thinning, can reduce the hole rate within the concrete , change the hole structure , improve glueing the function of forming of concrete every component part ;

(3) . Collect the material effect a little: Very small particle of fly ash even to is it among cement particle , pack the hole to distribute, play a role in getting to " thinning hole " , meanwhile , prevent glueing gathering each other of the cement particle, and make it in state of dispersing , help water of the mixture to react, the fly ash will not be totally with reacting with water result of the cement, can keep its " collecting the material effect a little " for a long time ;

(4) . Effect of the interface: It is the weak link in the concrete structure to collect the interface between the material and cement stone, width of transition area as water for dust than, collect there aren’t material , transition area have than grout body more, heavy hole. Mixing can reduce the regional width of the transition to add the fly ash , interfere Ca (OH ) orientation of 2 crystal in the transition area, improve the intensity of interface and density in the concrete.

(5) Performance of the fly ash concrete The change of the fly ash to concrete performance can be divided into three stages: 1 . Mix concrete stage newly: Influence the coagulation time of the concrete , is improving and easy , change rheology nature , can improve pump ,etc.;

(6) . The concrete stage while hardenning: Regulate the course of hardenning, reduce the heat of hydration; 3 . The concrete stage after hardenning: Raise the intensity on later stage , raise every durability, such as anti-permeability, resist the sulphate corroding, suppress the alkali - Collect the material and react etc..

3.1 Intensity

The fly ash has three kinds of influence on the intensity of concrete: Reduce water consumption , increase glued material content and reflect through the long-term volcanic ash that raises his intensity. The particle in the fly ash of low calcium is the silicon oxygen tetrahedron structure, one’s own activation is very low. In the final result of the cement, high alkaline water silicic acid calcium and crystallization of 2 colloid of Ca (OH ) are very low in intensity, especially Ca (OH) 2 ask vigorous to come 1-2% , stone of intensity only, but Ca (OH) 2 volume account for whole cement 25% , stone of volume. A large number of silicon , aluminium oxide that contain in the fly ash, can and high alkaline water silicic acid calcium 2 responses take place with Ca (OH ) 2 progressively, produce intensity than high low alkaline water silicic acid calcium , so , make cement stone water glue congeal quantity of material increase, and make its quality improved by a large margin , is favorable to the improvement of the intensity of concrete. Meanwhile, to is it can disperse cement particle to mix fly ash, make cement to be ink sufficient, improve closely knit degree of the grout , make the intensity of the interfaces of the aggregate and grout in the concrete improve. Fly ash is it draw intensity compare with contribution of the bending strength compression strength to be heavy to confront with each other, this is useful to resisting the performance of splitting of concrete. The elastic mould amount of the fly ash concrete is similar to compression strength, it is early and on the low side, improve progressively later stage , get 28d the constant basic concrete is raised by 5-10%. With to hold strength of wrapping up in reinforcing bar, 28d , fly ash of concrete is it form intensity the same with ,etc. basic concrete of grade basically to glue, but homogeneity, fly ash of concrete fine, is it form intensity person who test getting dispersed and kind than basic concrete to glue.

Water two times of the fly ash reacts and generally starts after the concrete builds 14d, when temperature is low , will reflect necessary time is longer. If strict with early intensity of the concrete, the mixing amount of the fly ash is unsuitable to exceed 30%, winter construction large volume at the concrete, the mixing amount of the fly ash is unsuitable to exceed 20% non-. Because modern concrete China and foreign countries add use of pharmaceutical, on one hand, reducible concrete mix and stir water consumption, it reduce by dust water than,of not lasting concrete density of cement; On the other hand, water-reducing agent can make cement silicic acid calcium ink Ca (OH ) produced 2 increase, help fly ash and water two times of 2 of Ca (OH ) to reflect , excites the activation of the fly ash, this effectual for early intensity to improve fly ash, in addition use fly ash activation excite pharmaceutical or in large volume use strong cement early among the concrete non-, can compensate mixing the impact on early intensity of concrete of fly ash too.

3.2 and easy

Whether fly ash there are the following several points to concrete and getting easy improvement function. ⑴.The high-quality fly ash contains more than 70% of the spherical vitreous bodies, too smooth to have raised angle the body surface of these spherical glass, performance is steady, play a kind of lubricated function which is similar to the bearing in the pump sending , shaking the course of smashing of the concrete; ⑵.Mix particle apt to gather group cement in the concrete newly, to is it can disperse cement particle effectively to mix fly ash, release more thick liquid body is it lubricate aggregate to come , help concrete work the improvement of performance ; ⑶.Mix fly ash can compensate detailed deficiency of bits in the detailed aggregate , cut off mortar base body secrete continuity , water of channel, the fly ash that at the same time quality is good can reduce the mixing water consumption of the concrete under the same consistency, make water dust of concrete than reduce light level to , is it secrete ink and emanate the phenomenon to reduce.

3.3 shrinking

The shrink of the concrete relates to the fact that the mixing water consumption and thick liquid body body of the concrete are accumulated, the less water consumption is, shrink the smaller. High-quality fly ash water requirement than smaller than 100% , mix and stir reduction , water of quantity make mix fly ash concrete after the 28d since dry to shrink and not dry to shrink little. Fly ash concrete is it is it mix with fly ash improvement of quantity reduce too to contract to do. But because water , fly ash of concrete reponse slowly, moisture evaporate fast, so between fly ash and to do epitome to be loud and very much heavy in early days concrete. For prevent early shrink , fly ash of concrete from fracture , should strengthen in early days raising to it

3.4 creeps

Issue in the past will it be age one day, intensity of concrete relatively low, issue is it it meets an emergency to be heavy than ordinary concrete too to creep corresponding age, but with ordinary concrete fly ash in one age one creep and was smaller than the ordinary concrete after this concrete of intensity.

3.5 carbonization performance

Fly ash concrete resist carbonization to be performance relatively poor. Cement consumption , fly ash of concrete reduce, cement water Ca (OH ) 2 too corresponding to reduce quantity that appear, and volcanic ash is it consume Ca (OH ) 2 of a certain amount too to react, make hydrogen ion index of the concrete reduce, will increase the speed of carbonization of the concrete. Unless especially at water in early days, fly ash the low in degree in response in volcanic ash,fly ash- there is the loose in structure in hole in system cement, CO2 , O2 , moisture ,etc. invade obstruction small, so carbonization is relatively large in depth. With the growth of one and gradual full play of the fly ash volcanic ash effect of age, the speed of carbonization will be reduced gradually. Carbonization , fly ash of concrete as water for dust in depth than and fly ash last increase of quantity and not increased to some extent. Than 0.5-0.55 in water dust, fly ash person who mix greater than 30% and under the general construction situation of competence, the depth of carbonization of the concrete can reach about 20mm in 15-17. Carbonization reacts and goes on within the range of certain relative humidity fastest, otherwise, the response is relatively slow. Under or is close to 100% 25% in the relative humidity, namely the occasion in the abundant dryness or water saturation of concrete, have more difficult to produce carbonization shrink concretes. In such concrete projects not contacted with the atmosphere as the foundation works ,etc., because of isolating with CO2, can take place carbonization react , so can mix and add the fly ash more , in order to fully reduce the heat of hydration of the concrete, improve the durability of the concrete. It is ultra to be adopt law quantity replace,water glue not lower than,mix carry on match ratio design water-reducing agent for admixture of main fact at the same time, can make fly ash concrete resist carbonization performance improve to some extent.

3.6 reinforcing bar corrosion

Reinforcing bar of concrete can it antirusts to be because concrete getting alkaline to form one pre-pressing passivation membrane in metal surface. Is it add fly ash to mix among concrete, on one hand it consume Ca (OH ) 2, reduce the alkali environment of the concrete; On the other hand, fly ash 2 responses turn into the hyrate with Ca (OH), raise closely knit degree of the concrete, increase the impermeability of the concrete and obstruction spread to the chlorine ion, hinder and prevent the invasion of CO2, can shield the reinforcing bar , so fly ash is mixed, in preventing the reinforcing bar corrosion, can offset because alkali degree reduce adverse effect that bring. The fly ash is on certain range (FA≤ 24% ) of mixing amount, have not influenced the reinforcing bar corrosion basically, even superior to the blank concrete. But if the mixing amount of the fly ash is greater than 30%, the carbonization of the concrete can make hydrogen ion index of the concrete dropped to about 8.5 from 12.5 , under so low a hydrogen ion index condition, the reinforcing bar is no longer passivated. Reach reinforcing bar position by depth as carbonization, complete carbonization , on terms that water and oxygen are permeated antiabrasion layer, reinforcing bar can take place but corrosion lead to the fact fracture of the concrete even destroy.

3.7 heat of hydration

The fly ash is very obvious to reducing the function of the concrete heat of hydration. Low calcium fly ash water in the first several days obvious degree have, heat of hydration produced only and half of cement. Replace 20% of the cement with fly ash in the concrete , can make the heat of hydration of concrete 7d drop by 11% . 1-28d in the issue, roughly for mix percentage of fly ash, Sheng Wen and percentage that heat of hydration reduce age. Fly ash is it can make heat of hydration time that peak appear is it appear to 3d to delay generally to mix among large volume concrete, can prevent the concrete from producing the temperature crack effectively .

粉煤灰高性能混凝土的工程应用

[摘要]

本文对粉煤灰高性能混凝土的各项性能作了详细的研究,并针对粉煤灰的掺入量对混凝土各

种性能的影响以及粉煤灰混凝土在施工中应注意的一些问题进行了分析和探讨。

1.概 述

粉煤灰作为一种工业废料,资源丰富、价格低廉,且含有大量的活性成分,是现代混凝土中非常重要的一个组分。优质粉煤灰合理地应用于混凝土中,不但能部分代替水泥,节省工程造价,而且,其特有的性能可以很有效地用于各种使用要求的混凝土中,改善和提高混凝土的性能,是高性能混凝土中的理想掺和料。在现代混凝土中,粉煤灰已经与水泥、集料、水、外加剂同样重要,成为混凝土中的一个组分。粉煤灰高性能混凝土是以耐久性为主要目标进行设计的混凝土。它以优异的耐久性(而不是高强度)为主要特征,也就是说,任何强度等级的混凝土都可以做成高耐久性混凝土。为达到高耐久性,粉煤灰混凝土应具备的性能是:在新拌状态有良的工作性,即高流动性而不离析、不泌水,以使成型均匀、密实,水化硬化早期的沉降收缩和水化收缩小,温升低,硬化过程干缩小,以达到无初始裂缝,硬化后的渗透性低。

2.对“粉煤灰效应”的认识

粉煤灰的“功能”和“效应”是所有粉煤灰材料技术和工程的应用基础。在混凝土中掺加粉煤灰,应对粉煤灰的功能作全面的认识,由原来对粉煤灰的“火山灰反应”及“经济组分”的概念,扩展到“粉煤灰效应”的技术意识,使得粉煤灰功能能够更好地服务于混凝土的性能改善和质量提高。粉煤灰在混凝土中的作用有以下几点: 1 .形态效应:粉煤灰的主要矿物组成是海绵状玻璃体、铝硅酸盐玻璃微珠,这些球形玻璃体表面光滑,粒度细,质地致密,内比表面积小,对水的吸附力小,这一系列的物理特性,不仅减小了混凝土的内摩擦阻力,有利于混凝土流动性的提高;而且,对混凝土有不同程度的“减水”作用; 2 .活性效应:粉煤灰的活性成分SiO2和AI2O3与水泥的水化产物在有水的情况下发生反应,生成水化硅酸钙(C-S-H)和水化硫铝酸钙(C-A-S-H),这些反应几乎都在水泥浆孔隙中进行,生成的水化产物填充、分割原来的大孔,使孔隙细化,可降低混凝土内部的孔隙率,改变孔结构,提高混凝土各组分的粘结作用; 3 .微集料效应:粉煤灰中的微细颗粒均匀分布在水泥颗粒之中,填充孔隙,起到“细化孔隙”的作用,同时,阻止水泥颗粒的相互粘聚,而使之处于分散状态,有利于混合物的水化反应,粉煤灰不会完全与与水泥的水化产物发生反应,能长期保持其“微集料效应”; 4 .界面效应:集料与水泥石之间的界面是混凝土结构中的薄弱环节,过渡区域的宽度随水灰比、集料吸附特性不同而异,过渡区域具有比水泥浆体更多、更大的孔隙。掺加粉煤灰能减小过渡区域宽度,干扰过渡区域中Ca(OH)2晶体的取向性,提高混凝土中的界面强度和密实性。

3.粉煤灰混凝土的性能

粉煤灰对混凝土性能的改变可分为三个阶段: 1 .新拌混凝土阶段: 影响混凝土的凝结时间,改善和易性,改变流变性质,提高可泵性等; 2 .硬化中的混凝土阶段: 调节硬化过程,降低水化热; 3 .硬化后的混凝土阶段: 提高后期强度,提高各项耐久性,如抗渗性、抗硫酸盐侵蚀性,抑制碱—集料反应等。

3.1强度

粉煤灰对混凝土强度有三种影响:减少用水量、增大胶结材含量和通过长期火山灰反应提高其强度。低钙粉煤灰中的微粒为硅氧四面体结构,自身的活性很低。在水泥的最终产物中,高碱性水化硅酸钙和Ca(OH)2胶体的结晶强度很低,特别是Ca(OH)2仅是托勃莫来石强度的1-2%,而Ca(OH)2 的体积占整个水泥石体积的25%。粉煤灰中含有的大量的硅、铝氧化物,能逐步与Ca(OH)2及高碱性水化硅酸钙发生二次反应,生成强度较高的低碱性水化硅酸钙,这样,不但使水泥石中水化胶凝物质的数量增加,而且也使其质量得到大幅度提高,有利于混凝土强度的提高。同时,粉煤灰的掺入可分散水泥颗粒,使水泥水化更充分,提高水泥浆的密实度,使混凝土中骨料与水泥浆的界面强度提高。粉煤灰对抗拉强度和抗弯强度的贡献比抗压强度还要大,这对混凝土的抗裂性能有利。粉煤灰混凝土的弹性模量与抗压强度相类似,早期偏低,后期逐步提高,到28d时可比基准混凝土提高5-10%。与钢筋的握裹力,粉煤灰混凝土的28d粘结强度基本与等标号的基准混凝土相同,但粉煤灰混凝土的均匀性好,粘结强度试验值的离散性比基准混凝土好

粉煤灰的二次水化反应一般在混凝土浇筑14d以后才开始进行,在温度低时,该反应所需的时间更长。如果对混凝土的早期强度有严格要求,粉煤灰的掺量不宜超过30%,冬季施工非大体积混凝土时,粉煤灰的掺量不宜超过20%。由于现代混凝土中外加剂的使用,一方面,可减少混凝土拌和用水量,减小水灰比,提高混凝土中水泥的浓度;另一方面,减水剂能使水泥中硅酸钙水化所产生的Ca(OH)2增多,有利于粉煤灰与Ca(OH)2的二次水化反应,激发粉煤灰的活性,这对于改善粉煤灰的早期强度是有效的,另外,使用粉煤灰活性激发剂或在非大体积混凝土中使用早强型水泥,也可以补偿粉煤灰的掺入对混凝土早期强度的影响。

3.2和易性

粉煤灰对混凝土和易性的改善作用有以下几点:⑴.优质粉煤灰中含有70%以上的球状玻璃体,这些球状玻璃体表面光滑无棱角,性能稳定,在混凝土的泵送、振捣过程中起着一种类似于轴承的润滑作用;⑵.新拌混凝土中水泥颗粒易聚集成团,粉煤灰的掺入可有效分散水泥颗粒,释放更多的浆体来润滑骨料,有利于混凝土工作性能的提高;⑶. 掺入粉煤灰可以补偿细骨料中细屑的不足,中断砂浆基体中泌水渠道的连续性,同时品质良好的粉煤灰在同样的稠度下能减少混凝土的拌和用水量,使混凝土中的水灰比降低到更小水平,减少泌水和离析现象

3.3收缩

混凝土的收缩与混凝土的拌和用水量和浆体体积有关,用水量越少,收缩也越小。优质的粉煤灰需水量比小于100%,拌和水量的减少使掺粉煤灰混凝土28d后的自干燥收缩和干燥收缩都小。粉煤灰混凝土的干缩也随粉煤灰掺量的提高而降低。但由于粉煤灰混凝土的水化反应慢,水分蒸发快,所以粉煤灰对混凝土的早期干缩影响很大。为防止粉煤灰混凝土的早期收缩开裂,对其更应加强早期养护。

3.4徐变

28天龄期以前,混凝土的强度较低,其相应龄期的徐变应变也较普通混凝土的大,然而与普通混凝土等强度的粉煤灰混凝土在此后所有龄期的徐变均小于普通混凝土。

3.5碳化性能

粉煤灰混凝土的抗碳化性能较差。粉煤灰混凝土中的水泥用量减少,水泥水化析出的Ca(OH)2 数量也相应减少,而且,火山灰反应也消耗了一定量的Ca(OH)2 ,使混凝土的PH值降低,会增加混凝土的碳化速度。特别在水化早期,粉煤灰火山灰反应程度低,粉煤灰-水泥体系孔结构疏松,CO2、O2、水分等入侵阻力小,因此碳化深度较大。随着龄期的增长和粉煤灰火山灰效应的逐渐发挥,碳化速度将逐渐降低。粉煤灰混凝土的碳化深度随水灰比及粉煤灰掺量的增加而有所增加。在水灰比为0.5-0.55,粉煤灰掺量不大于30%和一般施工水平的情况下,15-17年混凝土的碳化深度可达20mm左右。

碳化反应在一定的相对湿度范围内进行最快,否则,反应较慢。当相对湿度在25%以下或者接近100%,即混凝土在充分干燥或水饱和的场合,混凝土都不易产生碳化收缩。在基础工程等不与大气接触的混凝土工程中,由于与CO2隔绝,不会发生碳化反应,因此可较多地掺加粉煤灰,以充分降低混凝土的水化热,提高混凝土的耐久性。采用超量取代法,较低的水胶比,同时掺加以减水剂为主的外加剂进行配合比设计,可使粉煤灰混凝土的抗碳化性能有所改善

3.6钢筋锈蚀

混凝土中的钢筋能够防锈是由于混凝土的碱性(PH≥12.5)在金属表面形成一层致密的钝化膜。在混凝土中掺加粉煤灰,一方面会消耗Ca(OH)2 ,降低混凝土的碱环境;另一方面,粉煤灰又与Ca(OH)2反应生成水化物,提高混凝土的密实度,增加混凝土的不透水性和对氯离子扩散的阻力,阻碍和防止CO2的侵入,可对钢筋起保护作用,所以粉煤灰的掺入,在防止钢筋锈蚀方面,可以抵消因碱度降低带来的不利影响。粉煤灰在一定的掺量范围(FA≤24%),对钢筋锈蚀基本无影响,甚至优于空白混凝土。但是若粉煤灰的掺量大于30%,混凝土的 碳化可使混凝土的PH值由12.5降至8.5左右,在这样低的PH值条件下,钢筋不再钝化。当碳化深度到达钢筋位置,保护层被完全碳化,在水与氧气渗入的条件下,钢筋就会发生锈蚀而导致混凝土的开裂甚至破坏。

3.7水化热

粉煤灰对降低混凝土水化热的作用十分明显。低钙粉煤灰在头几天的水化程度并不明显,所产生的水化热仅及水泥的一半。在混凝土中用粉煤灰取代20%的水泥,可使混凝土7d的水化热下降11%。1-28d龄期内,大致为掺入粉煤灰的百分数,就是温升和水化热降低的百分数。在大体积混凝土中粉煤灰的掺入一般可使水化热峰出现的时间延缓至3d以后才出现,可以有效防止混凝土产生温度裂缝。

致 谢 信

经过半年的忙碌和工作,本次毕业设计已经接近尾声,作为一个本科生的毕业设计,由于经验的匮乏,难免有许多考虑不周全的地方,如果没有导师的督促指导,以及一起工作的同学们的支持,想要完成这个设计是难以想象的。

在这里首先要感谢我的指导老师郭晓燕老师。郭老师平日里工作繁多,但在我做毕业设计的每个阶段,从外出实习到查阅资料,设计草案的确定和修改,中期检查,后期详细设计,装配草图等整个过程中都给予了我悉心的指导。我的设计较为复杂烦琐,但是郭老师仍然细心地纠正图纸中的错误。除了敬佩郭老师的专业水平外,他的治学严谨和科学研究的精神也是我永远学习的榜样,并将积极影响我今后的学习和工作。

然后还要感谢大学四年来所有的老师,为我们打下土木专业知识的基础;同时还要感谢所有的同学们,正是因为有了你们的支持和鼓励。此次毕业设计才会顺利完成。

最后感谢建工工学院和我的母校—内蒙古科技大学对我的大力栽培。

此致

敬礼

致谢人:吕海波

2006.6.15

![]() , 1-2层为商场,3-6层为写字楼。

, 1-2层为商场,3-6层为写字楼。![]()

![]() ,梁宽b不宜小于柱宽的

,梁宽b不宜小于柱宽的![]() ,且不小于250mm。

,且不小于250mm。![]() ,且不小于梁高的1/4。

,且不小于梁高的1/4。![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 取次梁宽

取次梁宽![]() ,次梁截面

,次梁截面![]()

![]()

![]() 柱组合的轴压比设计值

柱组合的轴压比设计值![]() 考虑地震作用组合后柱压力增大系数,边柱取1.3,不等跨内柱取1.25,等跨内柱取1.2

考虑地震作用组合后柱压力增大系数,边柱取1.3,不等跨内柱取1.25,等跨内柱取1.2![]() 按简支状态计算的柱的负载面积

按简支状态计算的柱的负载面积![]() 折算在单位建筑面积上的重力荷载设计值,可根据实际荷载计算,也可以近似取为

折算在单位建筑面积上的重力荷载设计值,可根据实际荷载计算,也可以近似取为![]()

![]() 验算柱截面的上楼层层数

验算柱截面的上楼层层数![]() 柱截面面积

柱截面面积![]() 混凝土轴心抗压强度设计值

混凝土轴心抗压强度设计值![]() 框架柱轴压比限值,对一、二、三级抗震等级,分别取0.7、0.8、0.9

框架柱轴压比限值,对一、二、三级抗震等级,分别取0.7、0.8、0.9

![]() 干硬性水泥砂浆结合层

干硬性水泥砂浆结合层 ![]() 水泥砂浆找平

水泥砂浆找平 ![]() 水泥砂浆找平

水泥砂浆找平 ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() )

)![]()

![]() 钢框玻璃窗容重

钢框玻璃窗容重![]() )

)![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 粉刷:

粉刷:![]() 外墙

外墙![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() ,计算公式为

,计算公式为![]() ,式中

,式中![]() 为顶点位移,按D值法计算:

为顶点位移,按D值法计算:![]()

![]() ,

,![]()

![]()

![]()

水平地震作用分布 层间剪力分布

水平地震作用分布 层间剪力分布![]() 1/550。满足式

1/550。满足式![]() 要求。

要求。![]() )

)

![]() )

)

![]() 单向板

单向板 ![]() 单向板

单向板![]() 双向板

双向板

![]() 为均布荷载,代表梁自重。

为均布荷载,代表梁自重。![]()

![]() 分别为房间传给梁的均布荷载和梯形荷载。

分别为房间传给梁的均布荷载和梯形荷载。![]()

![]() 分别为边纵梁、中纵梁传给柱的恒荷载,包括梁自重、楼面板重和女儿墙等的重力荷载:

分别为边纵梁、中纵梁传给柱的恒荷载,包括梁自重、楼面板重和女儿墙等的重力荷载: ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()